Phase 1 of the Newberg/Dundee Bypass road in Oregon includes more than ten bridge structures, where the bypass crosses over creeks, wetlands, railroads, or travels over or under other local roads. The Corridor Theme is “Meandering River and Rolling Hills.” The theme includes an open form for bridge structures, which allows views for drivers under the structure and provides opportunities for smooth transitions into the surroundings. A “meandering river” concrete relief is stamped into the concrete railing and an ornamental “rolling hills” design is used where screening is required. That is where we come in! We rolled various tube steel to create the “rolling hills” on the bridges. We rolled: 16 lengths of tube steel 10" X 4" X .375" WALL A500 GR B (30 pcs total) bent the hard way to 15 different radii from 9 ft to 158 ft. 9 lengths of tube steel 12" X 8" X .375" WALL A500 GR B (16 pcs total) bent the hard way to 5 different radii from 28 ft to 58 ft. 19 lengths of tube steel 3" X 3" X .313" WALL A500 GR B (56 pcs total) to 26 different radii from 5 ft to 200 ft.

Blog posts tagged with 'square and rectangular tube bending'

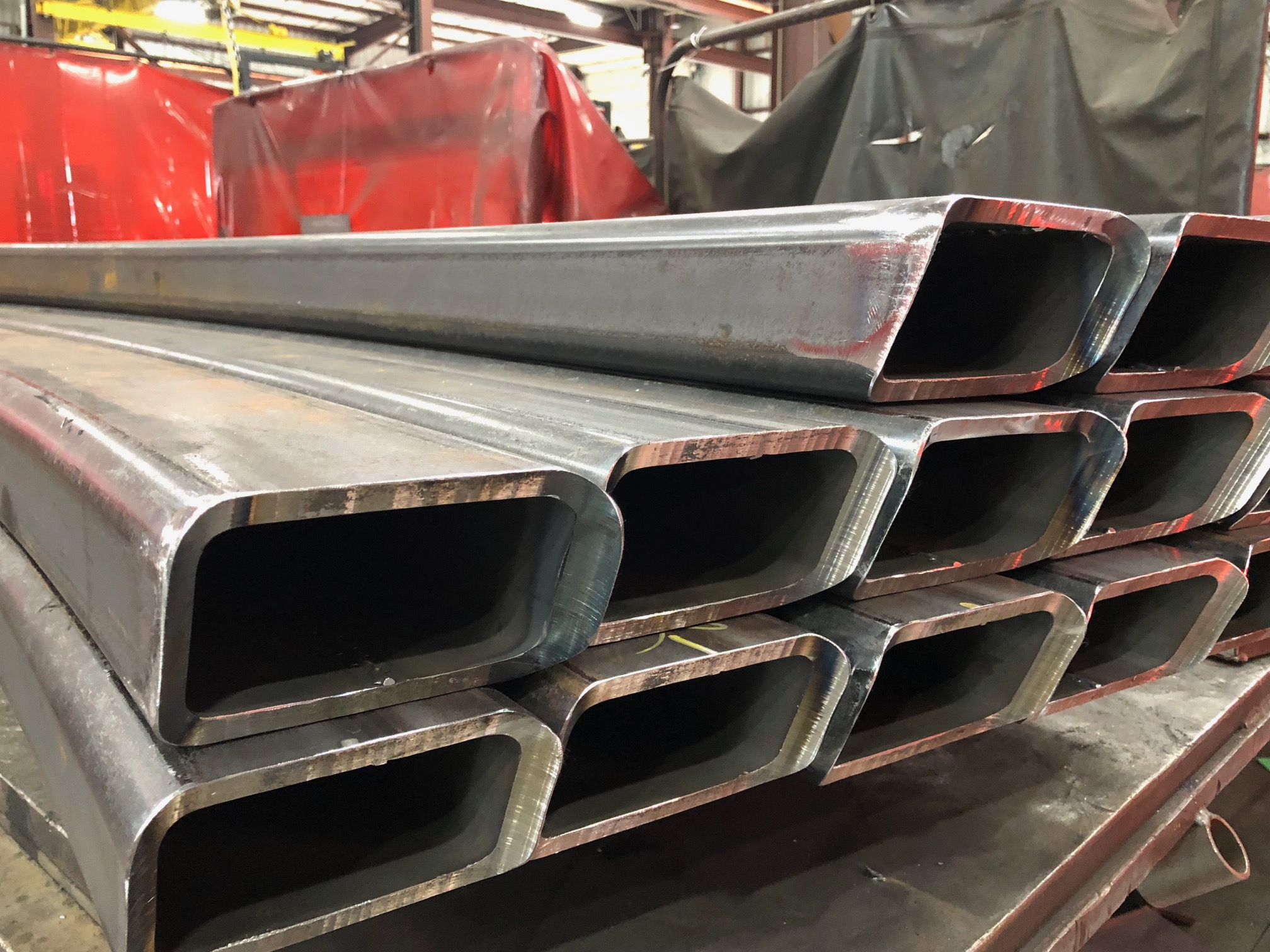

We recently spiral bent tube steel 12" X 8" X .625" WALL A500 GR B Spiral the Easy way to a 173” radius for a customer spiral staircase located in Utah. Square and rectangular tubing is also known as HSS (hollow structural steel). Albina has the ability to bend both square and rectangular tubing. For rectangular tubing we can bend both the easy way (against the weak axis) and the hard way (against the strong axis). We can even provide Multi-Plane bending where we are bending both the easy way AND the hard way. Albina is a unique shop in that we can bend very small square materials such as TS ½” x ½” x .049” wall all of the way up to very large materials such as TS 20” x 12” x .625” wall, which happens to be the largest size that mills produce. Albina actually has a larger capacity than TS 20” x 12” x .625” wall, which means we can bend materials larger then what the mills produce!

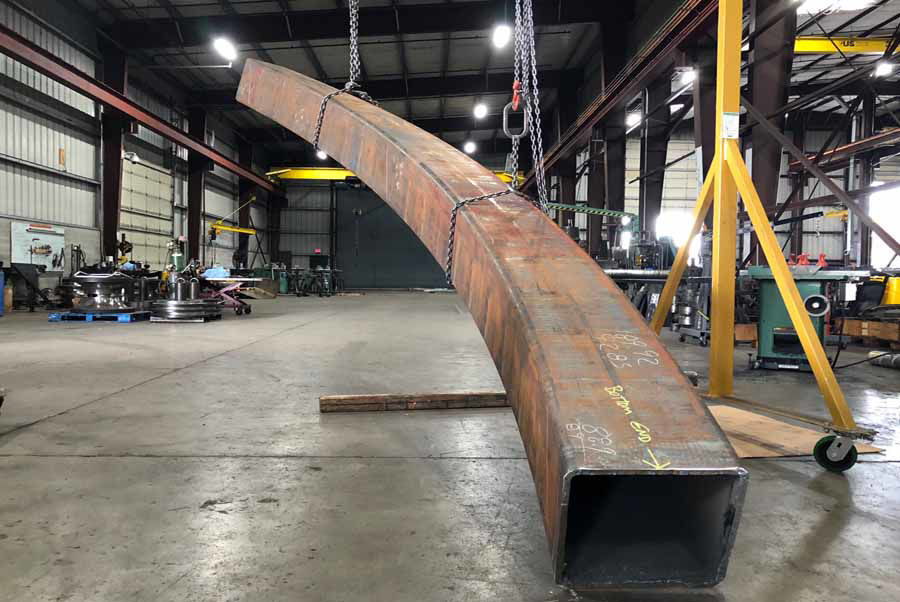

Albina recently used our induction heating process to spiral bend Tube Steel 16" X 16" X .625" WALL A500 GR B bent down to a an 18 foot radius for the new American Airlines headquarters in Fort Worth, Texas. The 1.7 million-square-foot complex, dubbed the “Trinity complex,” consists of constructing four seven-story buildings. It will cost at least $300 million to build and will house over 6,500 employees. There are 10 tower cranes on the project and there will be more than 1,000 construction workers on-site during the peak. It is scheduled to open during the second half of 2019. Including the 16" square, we have produced another set of spirals and have one in the queue. The one in the queue is Tube Steel 14" x 6" x .625" wall REALLY tight, exposed and bent to a 5'-6" radius on a 45° pitch. We already made a mock up for the job and all parties loved it. These are the type of bends that ONLY Albina can do! This is a really amazing project! Stay tuned for more pictures.

We currently have a job in progress that involves bending tube steel and doing some very complex end coping on the material for some custom skylights at the Philadelphia Museum of Art. The coped ends are VERY complex. Every machine shop we contacted to cope these ends and slot these ends all declined. With all of our technical expertise, we figured out how to do the ends in-house. It is the most complex end details we have ever worked with. Albina is bending, trimming, slotting and miter cutting 150 pieces of TS 5" X 3" X .375" WALL A500 GR B and TS 4" X 3" X .375" WALL A500 GR B per drawings down to a 4'8" radius. Our customer will do the remainder of the fabrication. Stay tuned for more pictures as we near completion of the job!

University of Gonzaga Steel Spiral Staircase[/caption]

University of Gonzaga Steel Spiral Staircase[/caption]- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2010

- 2009

- 2008

- 2007