Off-axis Bending

AISC Design Guide 33 Curved Member Design Section 2.2.2

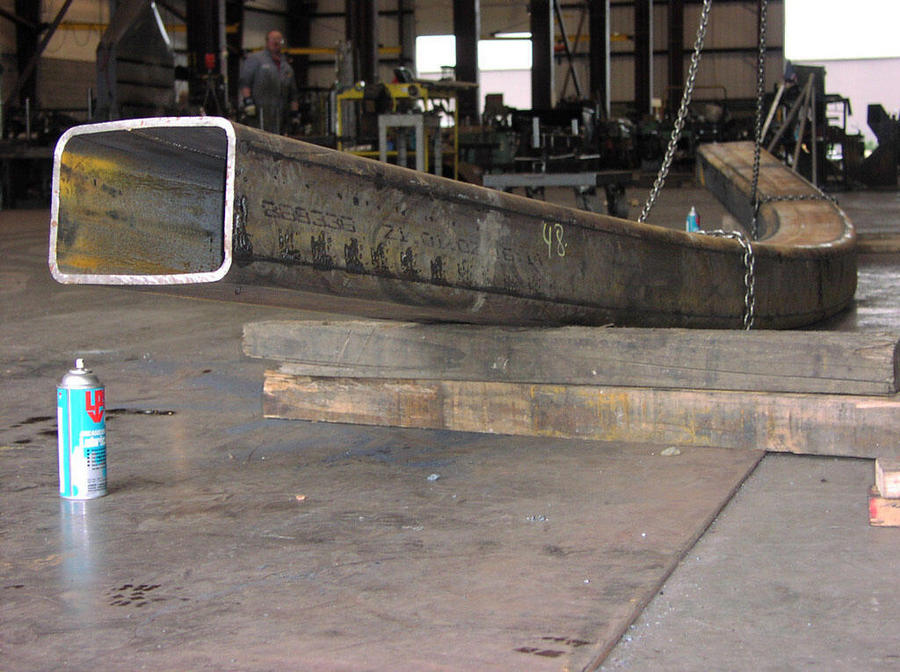

For off-axis bends, also called conical rolling, the member is curved about a non-principal or non-geometric axis. Most off-axis bends are fabricated with a constant rotation relative to the plane of curvature; however, they can also be formed with a variable twist along the member axis. Special tooling is often required to limit distortion and ensure dimensional accuracy. Off-axis bends are used when members are both curved and sloped, and a member axis must be parallel to the curved surface. In commercial structures, this can occur in canopies, arched roofs, and horizontal members in a dome. These members are also used for circumferential stiffeners in industrial cone-shaped plate structures, such as hoppers and stacks.

Less experienced bending companies will struggle with deformation when bending materials off-axis. It is recommended to ask the bending company to provide distortion estimates if you require off-axis bends to ensure you will be satisfied with the finished product.