Info Required For an Order

Geometry

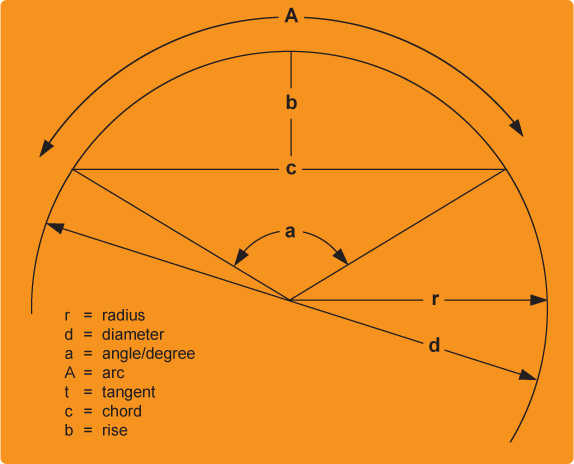

The graphic below depicts a simple single line drawing of the circular geometry components that relate to most bending applications. When specifying and detailing curved steel, there are a minimum number of components of this circular geometry that must be dimensionally specified. These components can be specified in different minimum combinations that will allow the bender to generate other required information for processing. Some examples of the combinations are as follows:

Radius and Arc:

The most basic information required for a bender-roller to curve steel.Chord and Rise:

Both dimensions, taken from the same work points, allow the bender-roller to calculate radius and arc.Radius and Degree/Angle:

Degree/angle, in conjunction with bend radius, allows the bender-roller to calculate arc.Radius and Chord:

Both dimensions, taken from the same work points, allow the bender-roller to calculate degree/angle or arc.Radius and Rise:

Both dimensions, taken from the same work points, allow the bender-roller to calculate degree/angle or arc.

*Additional information for bending may be required for processing depending on fabricated member requirements. For example, if tangents are required, the length of tangents needs to be provided separately from other dimensional components.

Produce to Customer Specifications

Ability to produce from customer supplied samples, drawings, fixtures or templates.

How to Order:

- Specify tolerances to be held on part shape

- Send drawings or print samples, if available

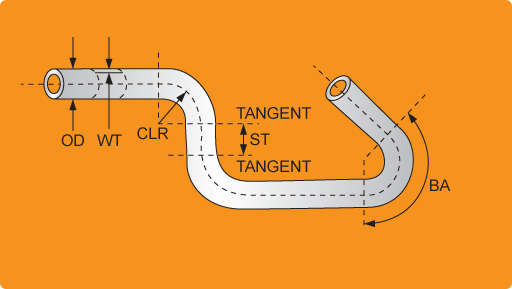

Specify:

Material, including alloy or temper

Outside diameter (OD) and wall thickness (WT)

Centerline radius (CLR)

Minimum straight bend between tangent points (ST)

Maximum bend angle (BA)

Formula to determine material required:

Degree of bend x radius of bend x .01745 + all straight material

Example:

90 degree bend, 6" radius, with 12" tangent on each end,

90 x 6 x .01745 = 9.423" + 24" = 33.423" total material length

*Distortion estimates and samples provided upon request to eliminate any uncertainty.