Beam & Wide Flange

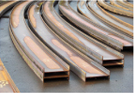

Beams and wide flange are both bent by Albina, from the very small sizes to the very large sizes.

We have the ability to bend wide flange and I-beam the easy way (against the weak axis) and the hard way (against the strong axis).

We can bend all types of beam / wide flange including aluminum, stainless and carbon steel.

I-Beam and wide flange are specified in similar fashions. An example callout for wide flange would be W36x210#. The W indicates Wide Flange. The 36 (in inches) indicates the approx. size of the wide flange when standing up (however, depending on the weight the size will vary). The 210# indicates the pounds per foot for the material.

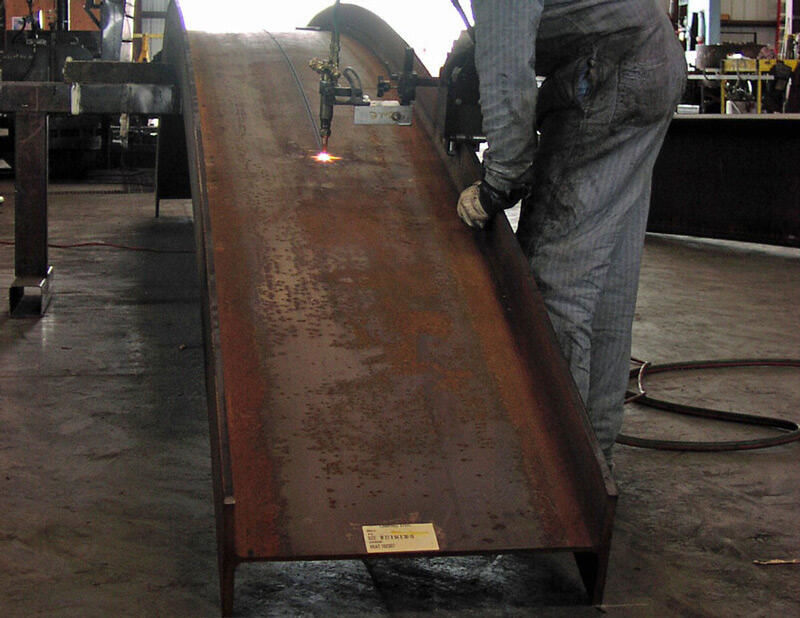

We have a number of different bending processes that allow us to bend these materials. The most common bending method is a roll bend or pyramid bends method. Straight material is inserted into the rolls; the rolls are then moved horizontally to put the desired radius into the material. The material can also be bent incrementally hot or incrementally cold. This is where small sections of material are bent at one time. When finished the section has a smooth curve to the bent section.

Other tools that sophisticated shops use to bend wide flange and I-beam are a web stretcher and mandrels. These tools are critical to use when bending the hard way as they keep the critical web from buckling or distorting.

The main difference between I-beam and wide flange is that I-beam has tapered flanges while wide flange has straight flanges.

We bend S3/W4 through W33x241#, W36x210# and W40x183#.

Carbon I-beam and wide flange (mill produced) is classified as ASTM A992 resulting in a yield point (psi) of 50,000 minimum.

We bend all stock lengths as well as non-stock lengths. Stock lengths come in 20 feet and then every 5 foot increment up to approximately 60 feet long.

Beam Splitting:

We can split any size wide flange into "T" and straighten, in our profile roll bending equipment, to mill tolerances.

SHOW ME MORE WORK EXAMPLES!

ARCHITECTURAL INSTALLS, SPIRAL STAIRCASES & OEM PARTS

Capacities Chart

| Section | 3D Image | 2D Image | Photo | Capacities |

|---|

| Beam the Easy Way (Y-Y Axis) |  |

|

|

S3/W4 through W33 x 241#, W36 x 210# and W40 x 183# |

| Beam the Hard Way (X-X Axis) |  |

|

|

S3/W4 through W36 x 230# |