Capacities Chart

Capacities Chart

| Section | 3D Image | 2D Image | Photo | Capacities |

|---|

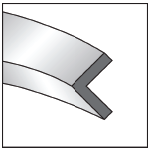

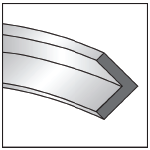

| Angle Leg Out |  |  |  | All sizes through 8" x 8" x 1¼" |

| Angle Leg In |  |  |  | All sizes through 8" x 8" x 1¼" |

| Angle Heel In |  |  |  | All sizes through 8" x 8" x 1¼" |

| Angle Heel Out |  |  |  | All sizes through 8" x 8" x 1¼" |

| Angle Heel Up |  |  |  | All sizes through 8" x 8" x 1¼" |

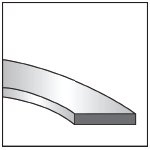

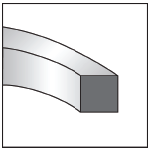

| Flat Bar the Hard Way |  |  |  | Any thickness and size through 2½" x 16" (section is dependent on thickness to width) |

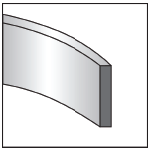

| Plate/Flat Bar the Easy Way |  |  |  | *Plate: 2-1/2" plate up to 10'0" in width *Flat Bar the Easy Way: Any thickness and size thru 4" x 22" *section is dependent on thickness to width |

| Square Bar |  |  |  | All Mill Produced Sizes |

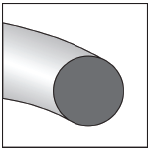

| Round Bar |  |  |  | All Mill Produced Sizes |

| Beam the Easy Way (Y-Y Axis) |  |  |  | S3/W4 through W33 x 241#, W36 x 210# and W40 x 183# |

| Beam the Hard Way (X-X Axis) |  |  |  | S3/W4 through W36 x 230# |

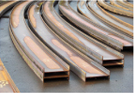

| Channel Flanges In |  |  |  | All Mill Produced Sizes |

| Channel Flanges Out |  |  |  | All Mill Produced Sizes |

| Channel the Hard Way (X-X Axis) |  |  |  | All Mill Produced Sizes |

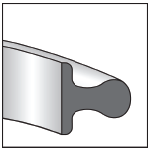

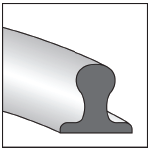

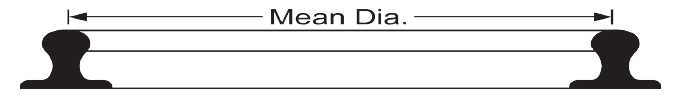

| Rail Ball In |  |  |  | All sizes up to approximately 175# |

| Rail Ball Out |  |  |  | All sizes up to approximately 175# |

| Rail Ball Up |  |  |  | All sizes up to approximately 175# |

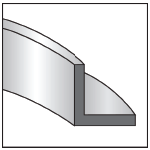

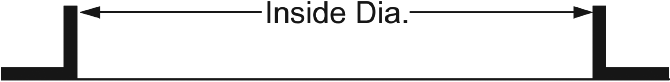

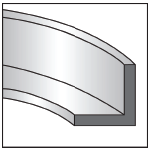

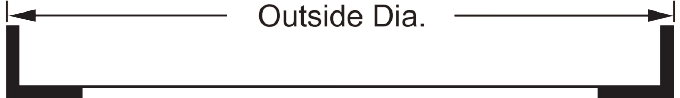

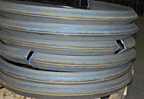

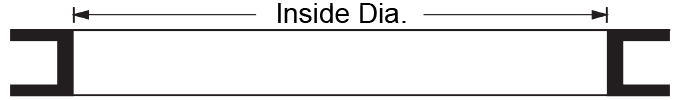

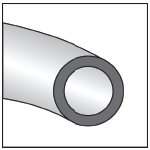

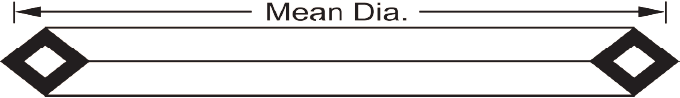

| Round Tube & Pipe |  |  |  | Roll/Cold Bending: 3⁄16" OD through 28" OD Induction/Hot Bending: 6" OD through 20" OD Rotary Draw/Mandrel Bending: ½" OD through 6" pipe (Sch80) |

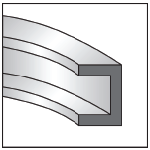

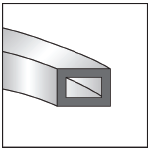

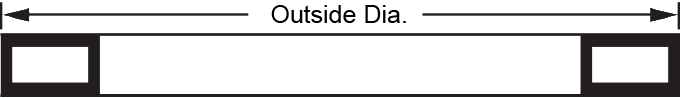

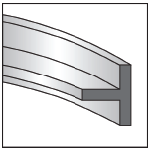

| Rectangular Tube the Hard Way |  |  |  | 20" x 12" x .625" (Maximum mill produced size-bending capacity is greater) |

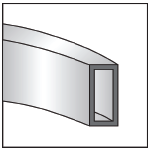

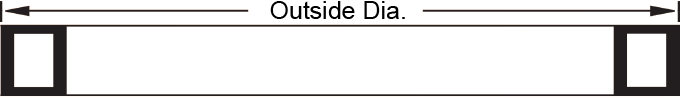

| Rectangular Tube the Easy Way |  |  |  | 20" x 12" x .625" (Maximum mill produced size-bending capacity is greater) |

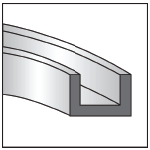

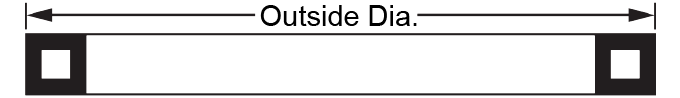

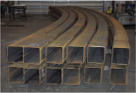

| Square Tube |  |  |  | 16" x 16" x .625" (Maximum mill produced size-bending capacity is greater) |

| Square Tube Diagonally |  |  |  | 16" x 16" x .625" (Maximum mill produced size-bending capacity is greater) |

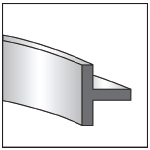

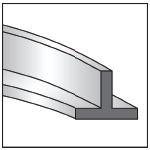

| Tee Stem In |  |  |  | All sizes through 12" Stems (weight per foot maximums would need to be calculated based on WF origin) |

| Tee Stem Out |  |  |  | All sizes through 12" Stems (weight per foot maximums would need to be calculated based on WF origin) |

| Tee Stem Up |  |  |  | All sizes through 12" Stems (weight per foot maximums would need to be calculated based on WF origin) |

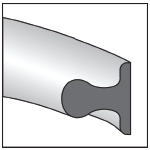

| Bulb Flat |  |  |  | All mill sized produced up to 430 mm x 20 mm (16.93" wide x .787" thick). |