Rolling & Pyramid Rolling

AISC Design Guide 33 Curved Member Design Section 2.3.1

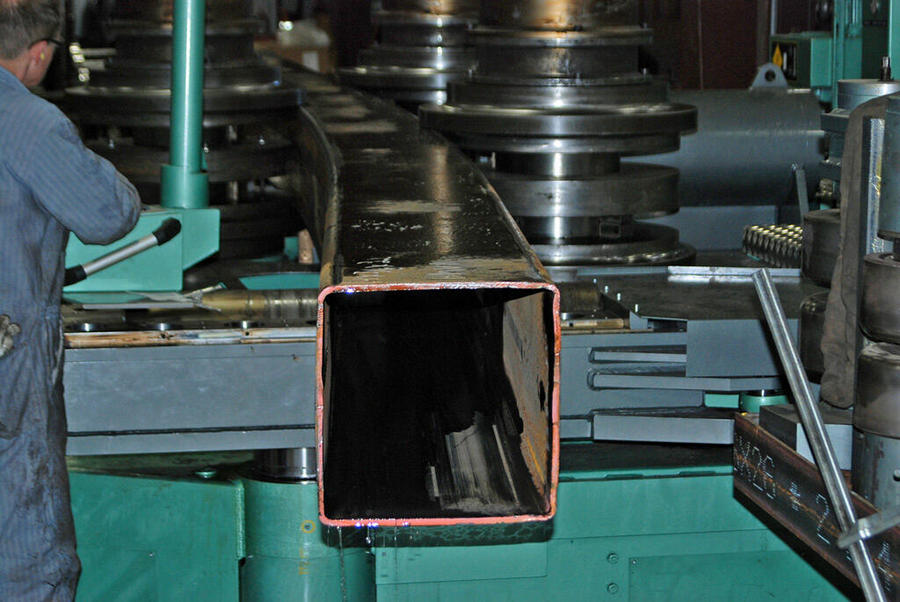

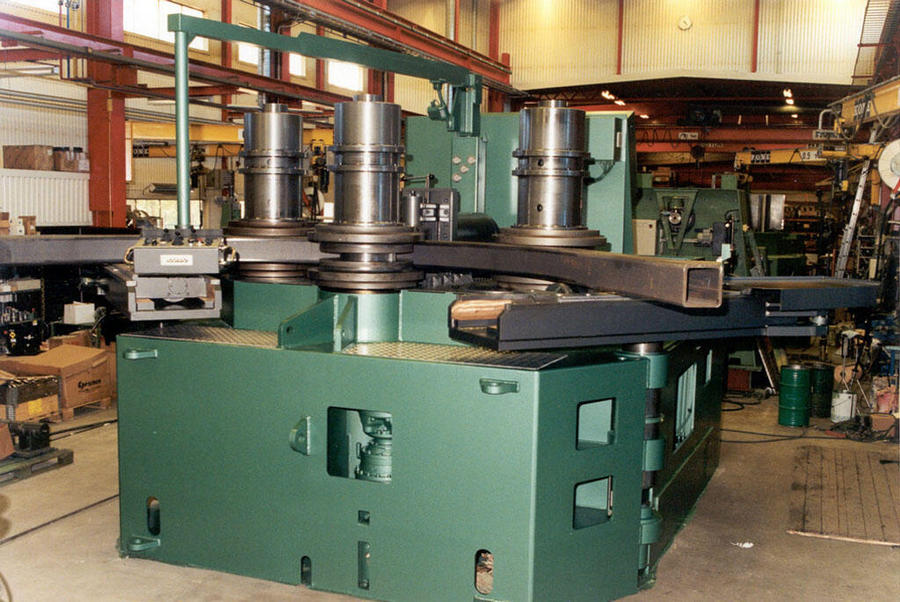

Pyramid roll bending is a cold-bending method where a member is bent progressively by repeatedly passing it through a set of three adjustable rolls in a pyramid arrangement. Force is applied by opposing rolls. The distance between rolls is manipulated before each pass, bending the member into successively smaller radii. This process is repeated until the proper curvature is formed. Pyramid roll bending can be used to provide curvature up to a 360° angle. When curving I-shaped sections, the tension and compression flanges tend to bend locally toward one another. These flange forces induce web compression stresses, potentially causing web buckling distortion. This can be controlled with supplementary rolls providing a restraining tension force on the inner surface of the tension flange on both sides of the web. In some cases, the web is restrained against buckling by compression rollers on each side of the web. To provide support during the bending operation, the rolls are contoured to match the cross-sectional shape of the workpiece. Contoured rolls can also be used for other cross-sectional profiles. Special rolls can be used to stabilize the cross-sectional elements and reduce distortion in common rolled shapes.