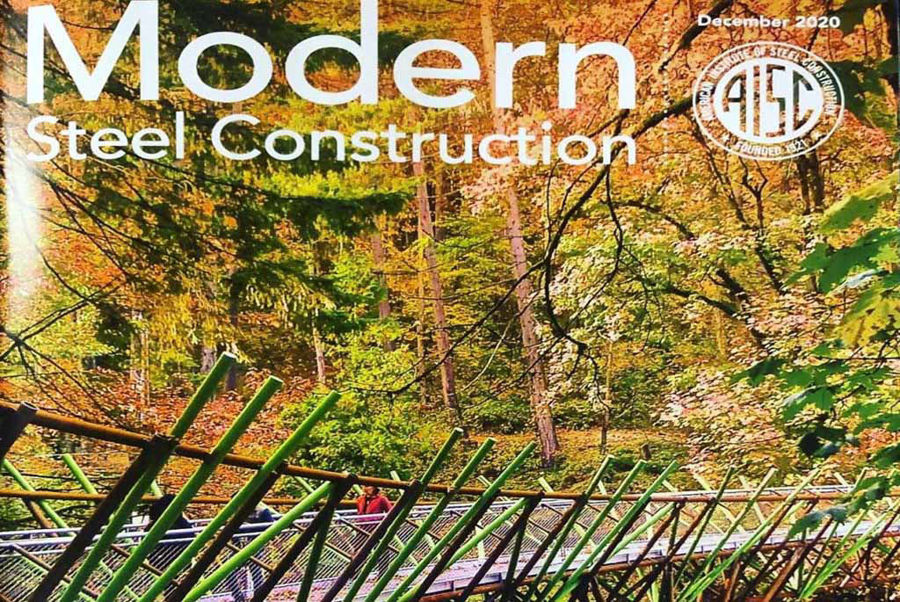

What’s Cool In Steel? Modern Steel presents tons of fun projects showcasing the use of cool steel in the December Issue, including the Barbara Walker Pedestrian Bridge along Portland’s Wildwood Trail. The Barbara Walker Crossing Footbridge is a two time CODA Award Winner. The bridge, designed by local artist, Ed Carpenter, is 178’ long measured at the center of its curving deck. Its basic structure is a tri-chord truss of rusting and painted steel. Carpenter’s design evokes imagery of the sword ferns and vine maples lining the entire length of the Wildwood Trail. This project is a collaborative effort of the Portland Parks Foundation in partnership with Portland Parks & Recreation (PP&R), the Portland Bureau of Transportation (PBOT), and Metro. Albina Co., Inc. bent 3½” SCH80 A847 and 5″ SCH40 A847 all rolled to various radii, as well as 1″ SCH40 A53B, 1½” SCH40 A53B, 1½” SCH80 A53B all rolled to various radii. (Photo Credit: Ed Carpenter).

Blog posts tagged with 'structural steel bending profiles'

Photo Credit: Univeristy of Oregon Track and Field.

Two major construction projects are just wrapping up at the University of Oregon and curved steel is at the forefront of both projects!

The Phil and Penny Knight Campus for Accelerating Scientific Impact Sky Bridge.

Albina Co., Inc. bent 22″ OD x 1″ Wall Carbon Steel Pipe to a 105 foot center-line radius for a signature sky bridge that spans Franklin Boulevard and serves as a connector between campus and other U of O research facilities. The $225 million, 160,000-square-foot first phase opened in the Spring of 2020. Click on the link in my BIO to take a virtual tour of the building. Photo Credit: Campus Planning & Facilities Management U of O.

“The Front Runner in Steel Bending. We Tower Above the Rest” We were thrilled to be an integral part of reconstructing Hayward Field at the University of Oregon. Hayward Field is the world-class home to @OregonTF.

Albina created the curved steel diaphragm used to support the roof structure and provided various bent materials to help construct the landmark tower at the northeast corner of the facility. Designers wanted to create a structure that was open and airy, allowing spectators to enjoy great views and natural daylight, in an intimate environment.

For the roof, we rolled 600 lengths, varying from 28’-0” to 75’-6” long, of 14" OD X .375" / .500 WALL A500-18 GRADE B&C. That is 1,500,000# lot weight (750 tons) of rolled steel, 32 inbound trucks and 90 outbound trucks. The 14” OD material was laid over the top of the plate that we bent for this project. We bent 300 lengths, varying from 3’-0” to 37’-0” long, of PLATE 1½" THICK X 16¾" WIDE A572 GR. 50 and PLATE 1½" THICK X 10" WIDE A572 GR. 50.

In addition to the iconic roof, the tower at Hayward (187 feet tall) creates a community landmark honoring the first 100 years of track and field at Oregon. We rolled 400 lengths, varying from 20’-0” to 60’-0” long, of Tube Steel 8" X 4" X .500" WALL A500 GR B, 8-5/8" OD X .625" WALL A500C WHEELED, 8-5/8" OD X .375" WALL A500C WHEELED, 8-5/8" OD X .250" WALL A500C WHEELED, and Flat Bar 3/8" X 4½" A36. That is 330,000# lot weight (165 tons) of rolled steel, 10 inbound trucks and 16 outbound trucks! Photo Credit: Oregon Track & Field.

Our work was extremely precise, and we had zero rejected parts by the fabricator, Fought & Co., Inc. When measuring the work points during fabrication, they never once had to heat up or adjust the bending. To make the erection process go smoothly, we marked every 3-4 feet on the centerline back of the pipe to assist in the layout process for the diagrid “fish-mouth” stubs, and up-stands for the roofing system.

Photo Credit: Linda Ulery

The Awards just keep on coming! The National Steel Bridge Alliance has awarded the Williams Creek Shoup Bridge in Salem, Idaho a Merit Award in the Medium Span bridges category. Albina was happy to be a part of the project and provided 145,000# of bent structural steel and HSS including:

W18 X 234# A992

4 lengths x 100 ft- bent the easy way to a 179 ft radius

2 lengths x 75 ft- bent the easy way to a 179 ft radius

TS 8" X 8" X .375" WALL A500 GR B

8 lengths x 53 ft: bent to a 304 ft radius.

Photo Credit: Don Perkins (Photos 2 & 3)

The AISC website has detailed information about the project, the design, the construction, erection, and more.

The Barbara Walker Crossing Footbridge, along the Wildwood Trail in Portland, Oregon, is the official winner of two prestigious CODA awards, organized by CODAworx, an online global design platform which celebrates the worlds best in public art. The footbridge won a People's Choice Award as voted on by the public, as well as an award in the transportation category. . Click to watch the YouTube Video featuring the bridge. The bridge, designed by local artist, Ed Carpenter, is 178’ long measured at the center of its curving deck. Its basic structure is a tri-chord truss of rusting and painted steel. Carpenter’s design evokes imagery of the sword ferns and vine maples lining the entire length of the Wildwood Trail. This project is a collaborative effort of the Portland Parks Foundation in partnership with Portland Parks & Recreation (PP&R), the Portland Bureau of Transportation (PBOT), and Metro. Albina Co., Inc. bent 3½" SCH80 A847 and 5" SCH40 A847 all rolled to various radii, as well as 1" SCH40 A53B, 1½" SCH40 A53B, 1½" SCH80 A53B all rolled to various radii. For more examples of curved steel pedestrian bridges that we have been a part of check out the Architectural & Structural Section of our website. (Photo Credit: Ed Carpenter).

Albina Co., Inc., was lucky enough to be the bender/roller for a beautiful spiral staircase that graces the lobby of one of the major tech companies headquartered in San Jose, California. Albina bent the following materials for the project:

Tube Steel 3" X 3" X .375" WALL A500 GR B

Channel C15 X 40# A572-50

3/8" THICK X 24" WIDE CORTEN PLATE

¼" THICK X 77¾" WIDE CORTEN PLATE

¼" THICK X 29½" WIDE CORTEN PLATE

The Inside stringer for the staircase was rolled to a 26’-11” radius and the outside stringer was rolled to a 32’-3” radius.

The Pacific Fleet Submarine Memorial Association operates USS Bowfin Submarine Museum & Park. It is the most visited submarine museum in the world. The museum aims to educate the public and honor veterans in a way that does justice to the brave men and women of the Silent Service. The USS Bowfin Submarine Museum & Park is undergoing a major improvement project and renaming itself The Pacific Fleet Submarine Museum at Pearl Harbor. In the video you can see one of the submarines in the bay. The ring resembles the hull of a submarine and will be featured as visitors enter the park. For more information and project renderings, click here. Albina bent the following materials for the project:

22,000# of rolled steel:

3 x 40 ft: TS 12" X 6" X .625" WALL A500 GR B. Net 3 pcs rolled the Easy Way to a 21 ft radius.

2 x 35 ft: TS 10" X 4" X .375" WALL A500 GR B. Net 2 pcs rolled the Easy Way to a 42 ft radius.

TS 12" X 4" X .375" WALL A500 GR B. Net 18 pcs rolled. Some rolled the Hard way and others rolled the Easy way. Radii ranging from 13 ft to 231 ft.

TS 10" X 6" X .375" WALL A500 GR B. Net 3 pcs rolled the Easy Way to a 24 ft radius.

W14 X 34# A992. Net 2 pcs rolled the Easy Way to a 24 ft radius.

4" X 4" X 3/8" ANGLE A36. Net 4 pcs rolled the Leg Out to a 24 ft radius.

Check back soon for final installation pictures! They are going to be spectacular!

Albina recently supplied 40,000# of bent steel for Kelli McGregor Square Mixed Use Development located outside Coors Field in Denver, Colorado. We bent the following materials.

TS 12" X 8" X .500" WALL A500 GR C

11 pcs bent the easy way

Various radii: 73 ft – 90 ft

TS 12" X 6" X .500" WALL A500 GR C

12 pcs bent the easy way

Various radii: 62 ft – 73 ft

To read more about the project and see renderings of what the final area will look like please read the article in Denver's Mile High Magazine.

Photo Credit: @haleyhillphotography

One of Southern California's iconic, flagship waterfront restaurant sites - 1360 North Harbor Drive along the North Embarcadero, is getting a facelift! The Port of San Diego and The Brigantine, Inc. began construction in July 2018 to redevelop Portside Pier including introducing four new dining concepts and enhancing the panoramic views of San Diego Bay for daily visitors. Albina Co., Inc. provided 60,000 pounds of various bent materials for the unique curved roof structure as well as for a signature spiral staircase that leads from the dock to the second floor public walkway and viewing deck.

Materials bent by Albina Co., Inc. included:

TS 14" X 6" X .500" WALL A500 GR B (6 pieces spiral bent the easy way as tight as a 17 ft plan view radius, 4 pieces bent the easy way as tight as a 17 ft inside radius.)

TS 12" X 6" X .500" WALL A500 GR B (8 pieces bent the easy way as tight as a 2’ 7” outside radius, 8 pieces spiral bent the easy way as tight as a 2’ 7” plan view radius.)

TS 8" X 8" X .500" WALL A500 GR B (84 pieces bent to various radii and configurations.)

TS 18" X 6" X .375" WALL A500 GR B (4 pcs bent the hard way.)

W10 X 12# A992 (9 pcs bent the hard way.)

W18 X 35# A992 (15 pcs bent the hard way.)

W16 X 26# A992 (2 pcs bent the hard way.)

W14 X 22# A992 (13 pcs bent the hard way.) Photo Credit: Encore Steel

Albina recently bent 37,000# of HSS for the Living Waters Express Car Wash in Aurora, Colorado. The concept for the Living Water Express Car Wash was to design a building that resembled flowing water. For more info on the project go to https://linktr.ee/AlbinaCoInc . To help our customer achieve their goals, we bent various materials including:TS 10" X 2" X .250" WALL A500 GR B- 10 pcs bent the hard way

TS 10" X 8" X .250" WALL A500 GR B- 6 pcs bent the hard way

TS 10" X 8" X .375" WALL A500 GR B- 6 pcs bent the hard way

TS 10" X 8" X .313" WALL A500 GR B- 4 pcs bent the hard way

TS 8" X 8" X .250" WALL A500 GR B- 4 pcs bent

3" X 3" X ¼" ANGLE A36- 36 pcs bent leg in

TS 8" X 2" X .250" WALL A500 GR B- 2 pcs bent the easy way

Photo Credit: University of Oregon Track & Field

We were thrilled to be an integral part of reconstructing Hayward Field at the University of Oregon. Hayward Field is the world-class home to @OregonTF. Albina created the curved steel diaphragm used to support the roof structure and provided various bent materials to help construct the landmark tower at the northeast corner of the facility. Designers wanted to create a structure that was open and airy, allowing spectators to enjoy great views and natural daylight, in an intimate environment. See https://linktr.ee/AlbinaCoInc for pictures, video and more!

For the roof, we rolled 600 lengths, varying from 28’-0” to 75’-6” long, of 14" OD X .375" / .500 WALL A500-18 GRADE B&C. That is 1,500,000# lot weight (750 tons) of rolled steel, 32 inbound trucks and 90 outbound trucks. The 14” OD material was laid over the top of the plate that we bent for this project. We bent 300 lengths, varying from 3’-0” to 37’-0” long, of PLATE 1½" THICK X 16¾" WIDE A572 GR. 50 and PLATE 1½" THICK X 10" WIDE A572 GR. 50.

In addition to the iconic roof, the tower at Hayward (187 feet tall) creates a community landmark honoring the first 100 years of track and field at Oregon. We rolled 400 lengths, varying from 20’-0” to 60’-0” long, of Tube Steel 8" X 4" X .500" WALL A500 GR B, 8-5/8" OD X .625" WALL A500C WHEELED, 8-5/8" OD X .375" WALL A500C WHEELED, 8-5/8" OD X .250" WALL A500C WHEELED, and Flat Bar 3/8" X 4½" A36. That is 330,000# lot weight (165 tons) of rolled steel, 10 inbound trucks and 16 outbound trucks!

Our work was extremely precise, and we had zero rejected parts by the fabricator, Fought & Co., Inc. When measuring the work points during fabrication, they never once had to heat up or adjust the bending. To make the erection process go smoothly, we marked every 3-4 feet on the centerline back of the pipe to assist in the layout process for the diagrid “fish-mouth” stubs, and up-stands for the roofing system.

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2010

- 2009

- 2008

- 2007