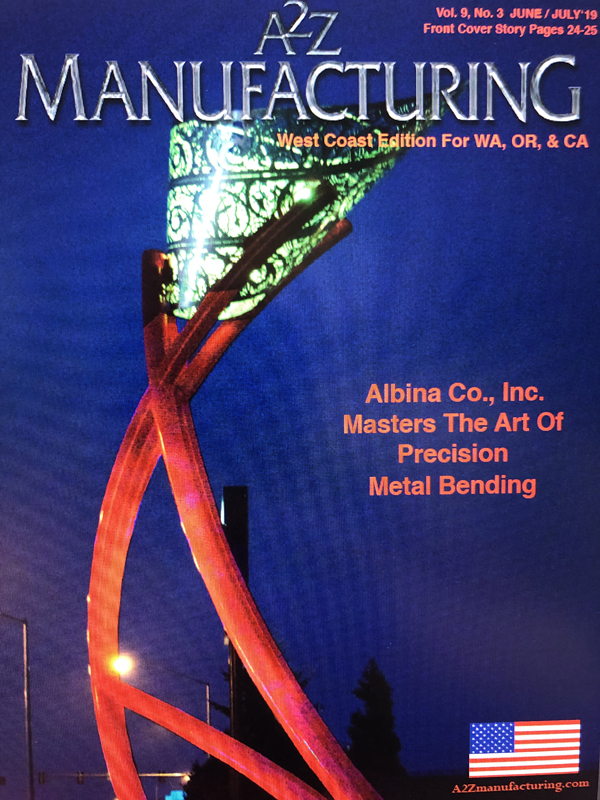

Photo Credit: Linda Ulery

The Awards just keep on coming! The National Steel Bridge Alliance has awarded the Williams Creek Shoup Bridge in Salem, Idaho a Merit Award in the Medium Span bridges category. Albina was happy to be a part of the project and provided 145,000# of bent structural steel and HSS including:

W18 X 234# A992

4 lengths x 100 ft- bent the easy way to a 179 ft radius

2 lengths x 75 ft- bent the easy way to a 179 ft radius

TS 8" X 8" X .375" WALL A500 GR B

8 lengths x 53 ft: bent to a 304 ft radius.

Photo Credit: Don Perkins (Photos 2 & 3)

The AISC website has detailed information about the project, the design, the construction, erection, and more.