Albina Co, Inc. produces consistent, accurate and repeatable rolled metal parts and components for various OEM and industrial business sectors. We produce small parts such as pipe spools, hydraulic lines, handles, brake bands, boiler tubes, heat exchangers, and coils.

We bend and fabricate pipe spools for a variety of different industries. We have the ability to provide small and large spools out of both carbon and stainless materials. Our qualified welders can TIG or MIG weld spools depending on customer requirements.

Our bent steel can be seen on various applications in the auto, marine, aviation, locomotive, agricultural and food processing sectors. Our bends are used on locomotive frames, boat frames, deck rails and even components for homeland security helping to protect our docks and ports. Here is an example of an extremely impressive bend for a commercial processing application:

Albina bent, torch cut out, fit and tack welded 10" SCH120 SA106B SMLS to a 12 ft radius.

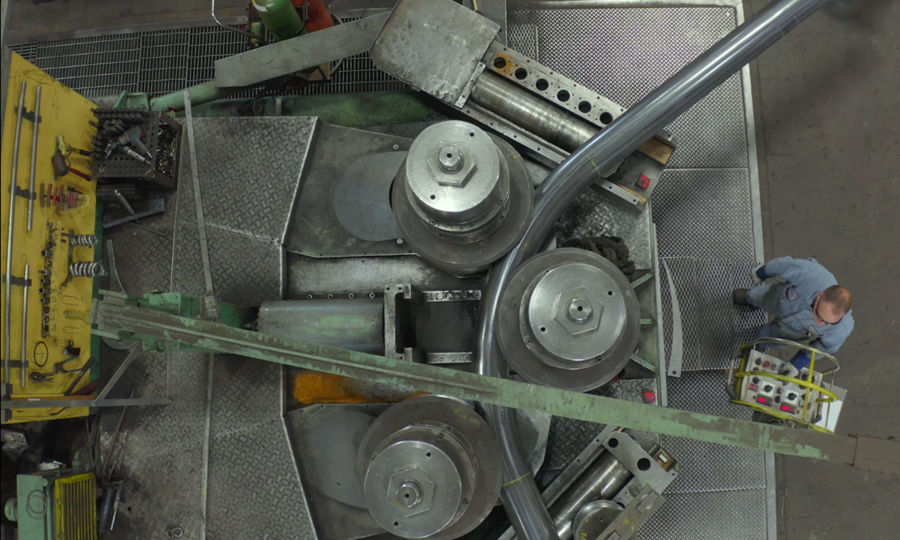

Our plate roll is consistently rolling custom tanks for countless industries, brake bands for industrial manufacturers and non-standard pipe diameters.

Our qualified crew has the skills required to fabricate your wear backs, or other pressure retaining components.

If your product needs to be opened, closed, held or picked up, we can produce your handle!

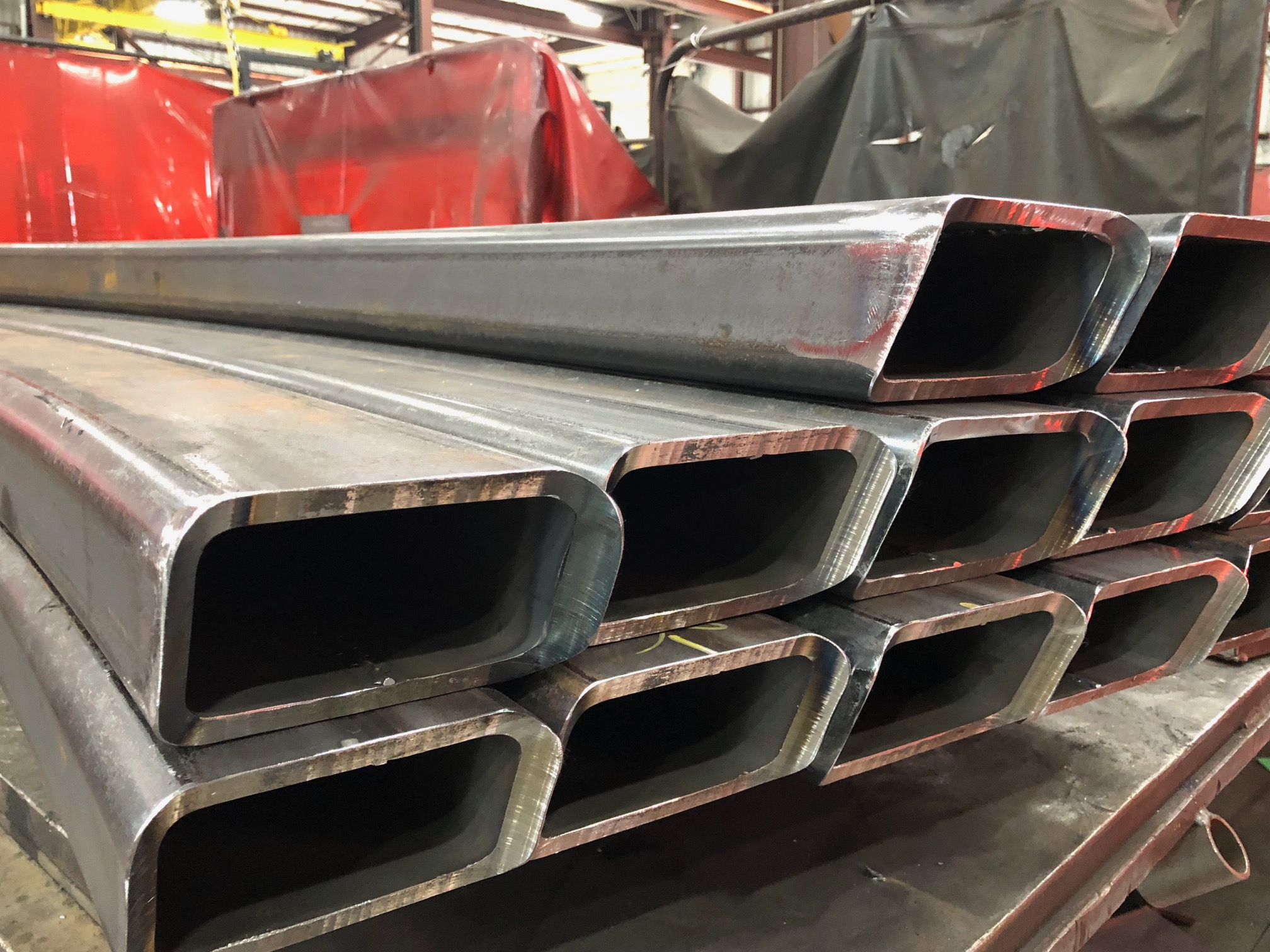

Albina has the expertise to bend coils to virtually any configuration. We coil all forms of material: pipe, tubing, square and rectangular. We also work with all types of material: carbon, stainless, aluminum, copper, zirconium, etc. One call can result in bent material fully fabricated with flanges, fittings, miscellaneous components, etc.

Most alternative energy projects require AESS (Architecturally Exposed Structural Steel) and Albina can bend to your AESS requirements. Team up with Albina on your next project so we can help you recognize savings and treat you to a stress free experience.