Photo Credit: @haleyhillphotography

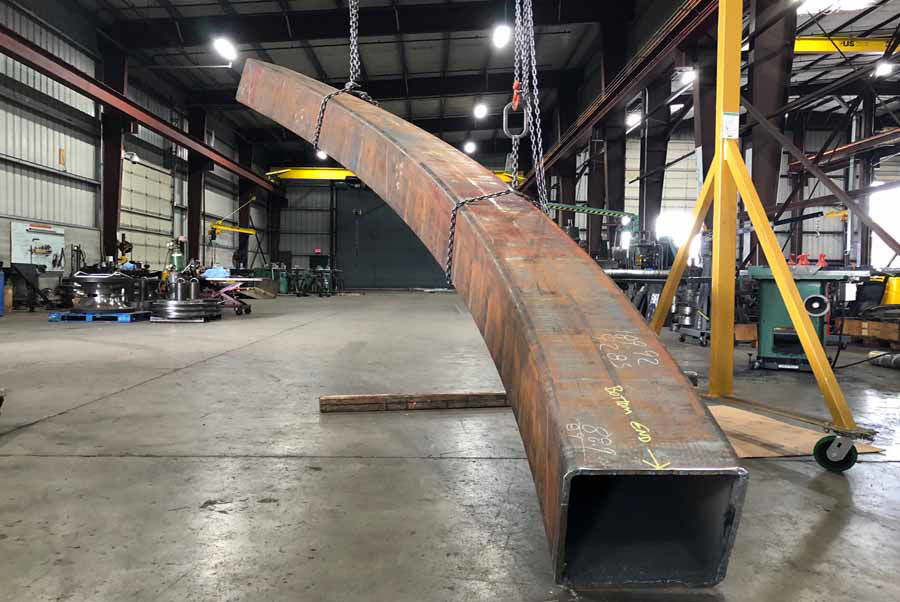

One of Southern California's iconic, flagship waterfront restaurant sites - 1360 North Harbor Drive along the North Embarcadero, is getting a facelift! The Port of San Diego and The Brigantine, Inc. began construction in July 2018 to redevelop Portside Pier including introducing four new dining concepts and enhancing the panoramic views of San Diego Bay for daily visitors. Albina Co., Inc. provided 60,000 pounds of various bent materials for the unique curved roof structure as well as for a signature spiral staircase that leads from the dock to the second floor public walkway and viewing deck.

Materials bent by Albina Co., Inc. included:

TS 14" X 6" X .500" WALL A500 GR B (6 pieces spiral bent the easy way as tight as a 17 ft plan view radius, 4 pieces bent the easy way as tight as a 17 ft inside radius.)

TS 12" X 6" X .500" WALL A500 GR B (8 pieces bent the easy way as tight as a 2’ 7” outside radius, 8 pieces spiral bent the easy way as tight as a 2’ 7” plan view radius.)

TS 8" X 8" X .500" WALL A500 GR B (84 pieces bent to various radii and configurations.)

TS 18" X 6" X .375" WALL A500 GR B (4 pcs bent the hard way.)

W10 X 12# A992 (9 pcs bent the hard way.)

W18 X 35# A992 (15 pcs bent the hard way.)

W16 X 26# A992 (2 pcs bent the hard way.)

W14 X 22# A992 (13 pcs bent the hard way.) Photo Credit: Encore Steel