Blog posts tagged with 'Structural Steel Bending'

$11 million Carmel, California 'Serenity' house for sale! Back in 2012, Albina bent wide flange W12 x 30#, W12 x 26# and W12 x 50# to help create the amazing exterior of this home. We bent 42 pieces the hardway to various radii as tight as 116 feet. The 2667 square foot home sits atop a cliff in Carmel, in central California. The exterior takes inspiration for its curves from the butterfly. The curved steel of the exterior has a unique effect on the interior spaces, making for interesting corridors and seating areas. I have several images of the project in process below, and I am working on securing the listing images and will post them as soon as I can. Until then, click on the following link to enjoy looking at the stunning images of a Butterfly-Inspired House on the California Coast!

Phase 1 of the Newberg/Dundee Bypass road in Oregon includes more than ten bridge structures, where the bypass crosses over creeks, wetlands, railroads, or travels over or under other local roads. The Corridor Theme is “Meandering River and Rolling Hills.” The theme includes an open form for bridge structures, which allows views for drivers under the structure and provides opportunities for smooth transitions into the surroundings. A “meandering river” concrete relief is stamped into the concrete railing and an ornamental “rolling hills” design is used where screening is required. That is where we come in! We rolled various tube steel to create the “rolling hills” on the bridges. We rolled: 16 lengths of tube steel 10" X 4" X .375" WALL A500 GR B (30 pcs total) bent the hard way to 15 different radii from 9 ft to 158 ft. 9 lengths of tube steel 12" X 8" X .375" WALL A500 GR B (16 pcs total) bent the hard way to 5 different radii from 28 ft to 58 ft. 19 lengths of tube steel 3" X 3" X .313" WALL A500 GR B (56 pcs total) to 26 different radii from 5 ft to 200 ft.

The downtown BART Berkeley (Bay Area Rapid Transit) station is conveniently located close to the University of California campus and to many shops, restaurants, theaters and other attractions, and has valet bike parking. Albina has been involved in several BART projects over the years and this is just the most recent one. We rolled various sizes of tube steel and angle including: Tube Steel 6" X 6" X .375" WALL A500 GR B- all bent to a 32 ft radius. Tube Steel 6" X 5" X .250" WALL A500 GR B- all bent the hard way to a 22 ft radius. All parts provided by Albina rolled, trimmed to length and notched for fabrication. Tube Steel 12" X 8" X .500" WALL A500 GR B. Bent by Albina the hard way to a 41 ft radius. Tube Steel 12" X 6" X .375" WALL A500 GR B. Bent by Albina the easy way to a 109 ft radius. Tube Steel 10" X 6" X .500" WALL A500 GR B. Bent by Albina the easy way to a 110 ft radius. 2½" X 2½" X ¼" ANGLE T316 S/S. Bent by Albina with the leg out to a 21 ft radius. Albina produces architecturally designed pedestrian bridges and walk-ways as well as motor vehicle and mass transportation bridges and support systems erected at transportation stations, universities, museums, large businesses, state park, etc.Here are some pictures. Check back for more pictures!

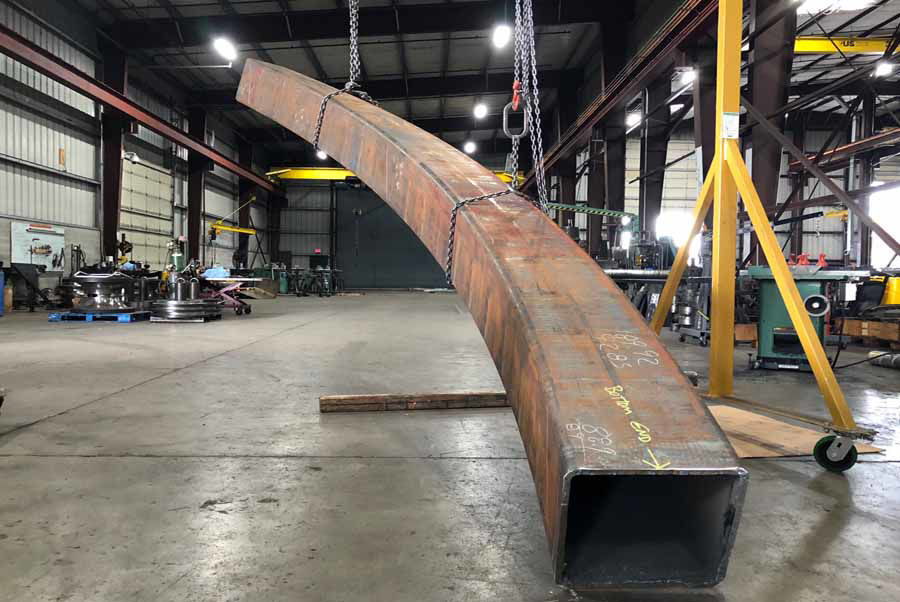

Albina recently used our induction heating process to spiral bend Tube Steel 16" X 16" X .625" WALL A500 GR B bent down to a an 18 foot radius for the new American Airlines headquarters in Fort Worth, Texas. The 1.7 million-square-foot complex, dubbed the “Trinity complex,” consists of constructing four seven-story buildings. It will cost at least $300 million to build and will house over 6,500 employees. There are 10 tower cranes on the project and there will be more than 1,000 construction workers on-site during the peak. It is scheduled to open during the second half of 2019. Including the 16" square, we have produced another set of spirals and have one in the queue. The one in the queue is Tube Steel 14" x 6" x .625" wall REALLY tight, exposed and bent to a 5'-6" radius on a 45° pitch. We already made a mock up for the job and all parties loved it. These are the type of bends that ONLY Albina can do! This is a really amazing project! Stay tuned for more pictures.

Our new machine is up and rolling! This master bender machine offers the new and innovative iRoll camera system, allowing operators to view the part being bent compared to a radius template on the control screen. This is a new way to make quality and consistent parts. Another innovation with the master bender is the machine's ability to “learn and remember” how different materials bend, where the rolls need to be positioned, and how much spring back is associated with a bend / material. This machine is a great fit for our shop, its size puts it right between our current Roundo R7 and R11 machines. Allowing us to reallocate work from two machines to three machines which should certainly help with our scheduling flexibility. The MCP30 will allow us to bend up to 8” x 8” angle, 9” square HSS, W16 the easy way / W12 the hard way and 14” Sch20 pipe / 12” Sch40 pipe.

We recently went on a family trip to Kona, Hawaii. We work extremely hard and we play extremely hard! We zip-lined for the first time! All of us went upside down and no hands over spectacular river gorges, water falls and lava tubes! The next day, we swam with dolphins in the wild and also came upon a pelagic manta ray measuring 8 feet wide that had never been spotted in the Hawaiian waters! The kids had the amazing pleasure of naming the manta ray "Freedom"![/caption]

We recently went on a family trip to Kona, Hawaii. We work extremely hard and we play extremely hard! We zip-lined for the first time! All of us went upside down and no hands over spectacular river gorges, water falls and lava tubes! The next day, we swam with dolphins in the wild and also came upon a pelagic manta ray measuring 8 feet wide that had never been spotted in the Hawaiian waters! The kids had the amazing pleasure of naming the manta ray "Freedom"![/caption]- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2010

- 2009

- 2008

- 2007