Sponsored by the American Institute of Steel Construction, the Innovative Design in Engineering and Architecture with Structural Steel (IDEAS2) recognizes projects where structural steel has been utilized in an innovative manner. We have been an integral part of many award winning projects, but this year, our curved steel was featured on the award-winning project of the UC Davis Jan Shrem and Maria Manetti Shrem Museum of Art. In honor of this years award winners, the AISC produced a high quality coffee table flip Book of the winners. The UC Davis Jan Shrem and Maria Manetti Shrem Museum of Art is featured on pages 39 and 40 Feel free to check out the whole book to see the entire list of winners. [caption id="attachment_1092" align="aligncenter" width="1200"] Curved Steel Entry [/caption] [caption id="attachment_1091" align="aligncenter" width="1200"] 50,000 Square Foot Permeable Roof[/caption] [caption id="attachment_1093" align="aligncenter" width="1200"]

50,000 Square Foot Permeable Roof[/caption] [caption id="attachment_1093" align="aligncenter" width="1200"] Overview of Curved Roof Structure[/caption]

Overview of Curved Roof Structure[/caption]

Blog posts tagged with 'Structural Steel Bending'

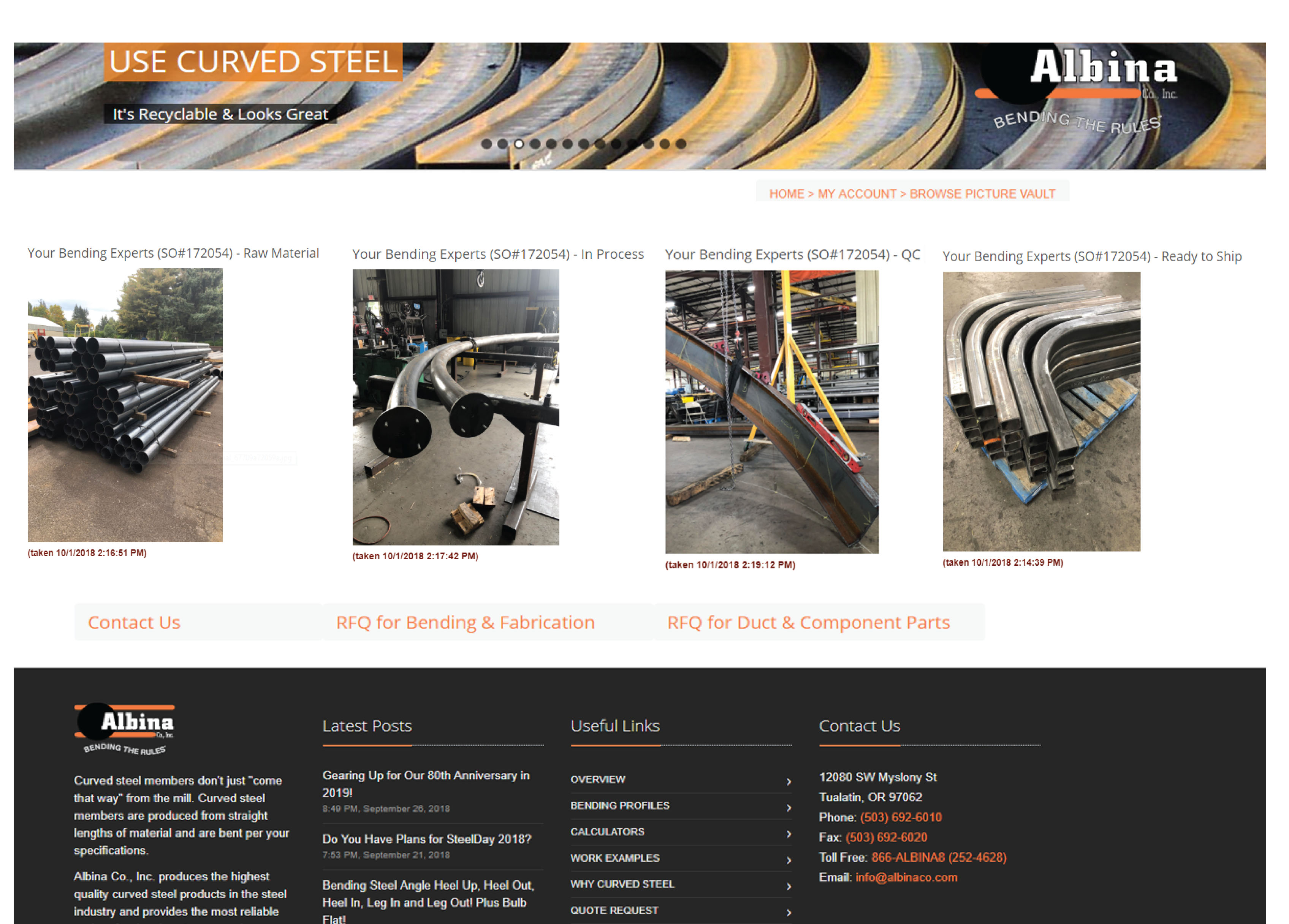

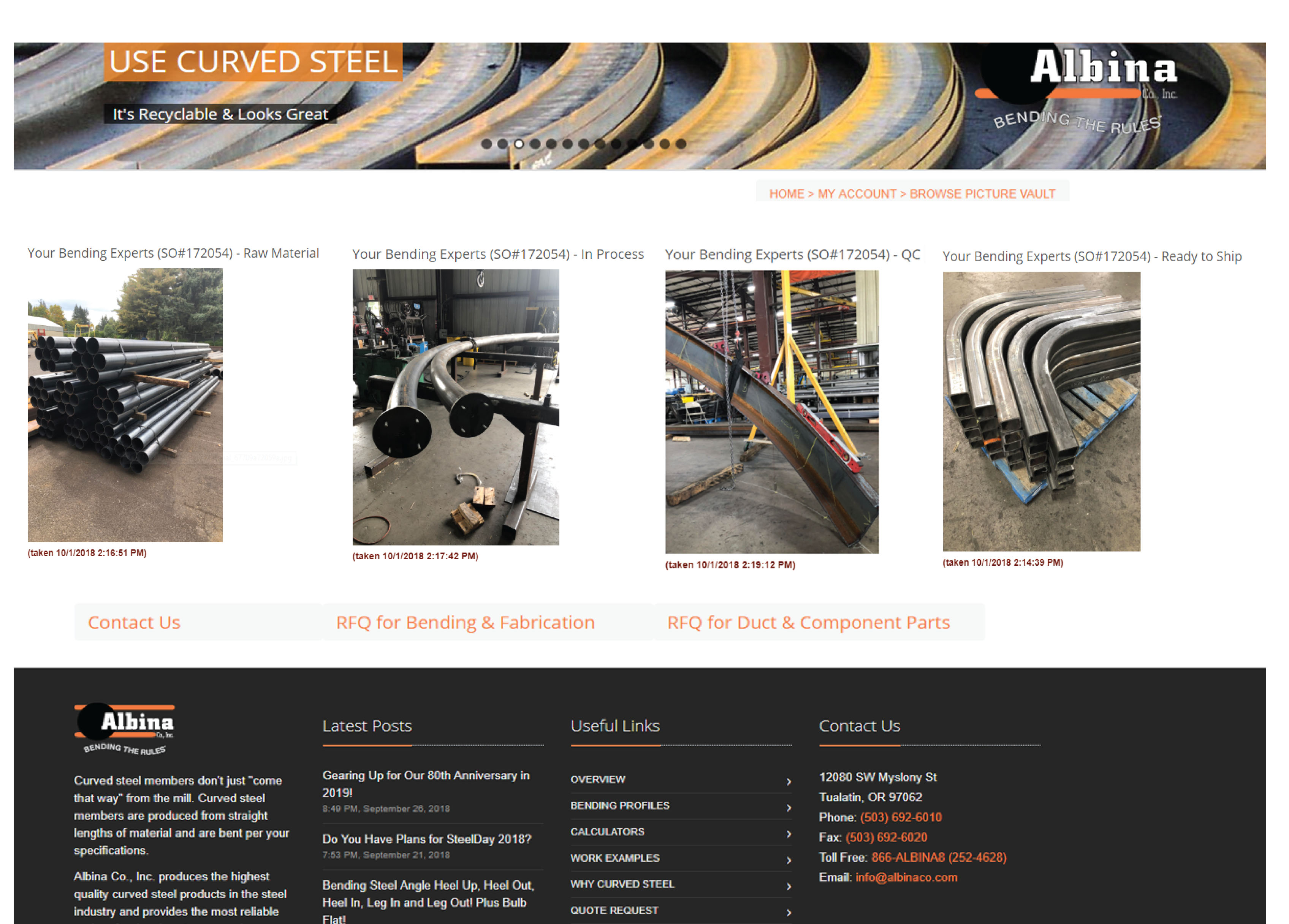

This is just the first phase of the secure site. Our plan is to provide a resource for customers to view and track other items including invoices, packing slips, order confirmations, etc.

This is just the first phase of the secure site. Our plan is to provide a resource for customers to view and track other items including invoices, packing slips, order confirmations, etc.We recently completed bending 3 lengths x 45 feet of Wide Flange W8 X 35# A992 Bent the easy way to a 16’ 6” radius. 120° of content. Albina rolled, trimmed, drilled and assemble complete the three lengths displayed in the front of these images. These large span bends were for one of the leading formwork and scaffolding companies in the construction industry.

Once pictures are taken and uploaded to Albina’s internal picture vault, the project manager at the customer site will receive an email with a secure login username and password, as well as a link letting them know that they have new pictures ready to view. Pictures will be categorized based on Purchase Order Number and Project Name and will remain available for viewing indefinitely. If customers like the pictures posted in the vault, they are welcome to contact us and we will provide a JPEG image for both internal or external use. This is just the first phase of the secure site. Our plan is to provide a resource for customers to view and track other items including invoices, packing slips, order confirmations, etc.

Once pictures are taken and uploaded to Albina’s internal picture vault, the project manager at the customer site will receive an email with a secure login username and password, as well as a link letting them know that they have new pictures ready to view. Pictures will be categorized based on Purchase Order Number and Project Name and will remain available for viewing indefinitely. If customers like the pictures posted in the vault, they are welcome to contact us and we will provide a JPEG image for both internal or external use. This is just the first phase of the secure site. Our plan is to provide a resource for customers to view and track other items including invoices, packing slips, order confirmations, etc.

We bend all sizes of angle that the mill produces, up to 8” x 8” x 1¼”. We can bend all types of angle as well; including aluminum, stainless and carbon steel. Carbon angle (mill produced) is classified as ASTM A36 resulting in a yield point (PSI) of 36,000 minimum. We bend all stock lengths as well as non-stock lengths. Stock lengths range from 20 to 40 feet. Angle is produced with equal legs and unequal legs. Unequal legs would measure differently on the horizontal leg versus the vertical leg. We have the ability to bend angle with the leg in, leg out, heel in, heel out and heel up. We also have the ability to bend bulb flat. Bulb flat is similar to angle with one of the legs cut down to a very short "stub". We can bend bulb flat with the stem out and the stem in. We can bend all mill sizes produced up to 430 mm x 20 mm (16.93” wide x .787” thick). Bent angle can be used for many different applications. The most common application would be angle flanges which are full circles that are used to join sections of pipe together. Bent angle is also used for canopies, roof trusses and tunnel shoring applications.

Albina bent 55,000# of wide flange W24 X 76# A992, W30 X 108# A992, W36 X 135# A992, W36 X 170# A992 for the Murray Park Amphitheater in Salt Lake City, Utah. Over a planning period that lasted several years, the city received input from patrons and citizens that focused on the needs and wants for improvements to the amphitheater. The largest improvement to the amphitheater was a curved steel roof over the stage and orchestra pit. “In the summer, we have microburst storms that roll in at around three or four in the afternoon and rain out events,” Sorenson said. “The stage can also get very hot, which limits what you can do in the afternoon. If we had a roof, we wouldn’t have to cancel. It would allow us to keep events running.” One of Albina Co., Inc.'s slogans over the years is "We've Got You Covered" and in this instance, we truly did! The wide flange was all bent the hardway to a radii range of approx. 90 ft – 100 ft. and it was all bending to AESS (Architecturally Exposed Structural Steel Standards).

We spent this last weekend in Seattle as we took our son and some friends up to a Mariners game. We had Saturday morning to spend in the city, and everywhere we looked, we stumbled upon projects containing curved steel that we have been a part of! The Jimmy Hendrix Museum, The Spheres and Spiral Staircase at The Spheres, the New Spiral Staircase in the Space Needle, the Canopy at the Seattle Great Wheel, the Dale Chihuly Garden and Glass Museum, the pedestrian bridge at the Museum of Flight, and art projects outside of corporate offices. The list goes on! What a true experience to see Brian showing the kids all of the curved steel projects Albina has done over the years! It was a great teaching moment to explain how the entire process works from the beginning of a project to the end and how all the different players work together to accomplish one final product. We were extremely proud to be the steel bender of choice for these amazing projects in the Pacific Northwest. And stay tuned, there are great things happening in the PNW and many more high profile projects coming up!

We recently completed a project consisting of 82,000# of bent steel for "The Village Medford Center" in Medford, Oregon. The Village is the center of a major environmental and architectural transformation at Medford Center, which is the premier entertainment-oriented shopping and dining experience in Medford, Oregon. Part of the architectural upgrades included a new dynamic sign program featuring an arched entryway with an illuminated pendant pine cone sculpture and a new 80-foot tall architectural tower, that will be visible from the I-5 freeway. We rolled 24 lengths of Tube Steel 16" X 8" X .500" WALL A500 GR B the Hardway to a 42 foot inside radius. All material was bent to AESS standards (without heat)! We also rolled 16 lengths of Tube Steel 6" X 6" X .500" WALL A500 GR B down to as tight as a 27 foot radius.

- 2026

- 2025

- 2024

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016

- 2015

- 2014

- 2013

- 2012

- 2010

- 2009

- 2008

- 2007