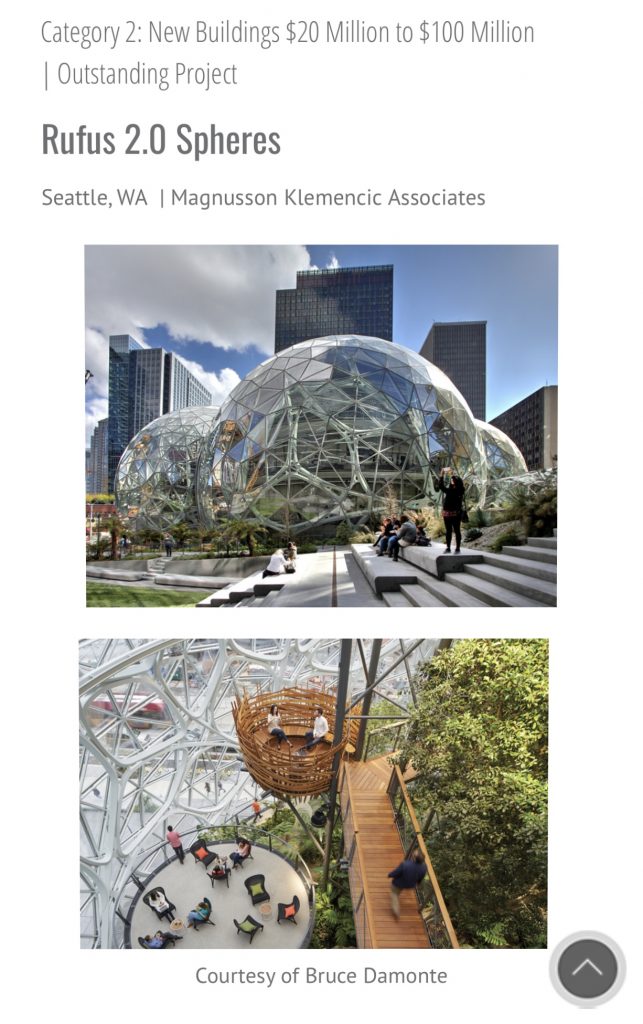

The National Council of Structural Engineers Associations (NCSEA) recently announced the 2019 Excellence in Structural Engineering Awards in the December issue of Structure Magazine. The Rufus 2.0 Spheres in Seattle, WA. Was awarded the “Outstanding Project” for New Buildings $20 Million to $100 Million. We worked with some of our amazing partners in the PNW on this project! Albina's portion included bending 750,000# and 1,050 pieces of rectangular tube steel bent the easy way and a portion bent off-axis for this project. Almost 8 miles of welding work and grinding was avoided because of Albina's ability to bend a portion of the project. Almost NO correction was needed during fabrication or erection as the bends fit to the fixtures within 1/32nd of an inch!