Carving pumpkins is a family tradition in the Smith House, a tradition that started 20 years ago with one of mine and Jaime's first dates. But like most events in our household, it is not something we just do without thorough planning and preparation. We follow a strict set-up, we have our designs in mind before we start, we have all of the tools we need at hand, we tackle challenging designs, and most importantly, we have Chinese food waiting for us when we are done! But in all seriousness, the steps we go through to carve pumpkins are very similar to the ones we go through when dealing with a project involving a curved steel component.

1) Plan Ahead: Buy Your Pumpkin Shortly Before Halloween

2) Buy Your Pumpkin from a Pumpkin Patch or Supermarket

3) Select a Healthy Pumpkin Free of Nicks, Bruises and Cuts

4) Pick the Size You Need

5) Choose a Design Before You Start Carving

6) Choose a Method for Carving Your Pumpkin

7) Trace Your Design on the Pumpkin

8) Set Up a Spacious Work Area

9) Select the Right Tools

10) Remove the Filling

11) Carve Your Design

12) Display Your Pumpkin

1) Plan Ahead: Early Involvement of Key Players, especially Your Bender/Roller.

2) Buy the Steel: Have Us Quote Your Job Labor + Material or Purchase Your Own Steel from a Service Center and Have it Delivered To Us

3) Select the Material that is Right for Your Job: HSS, Pipe, Tube, Angle, Channel, Wide-Flange, I-Beam?

4) Pick the Size You Need: Use our Handy Calculators or refer to our quote indicating the lengths we require to successfully bend your project.

5) Work with the Engineer, Architect or Bender/Roller on the Project to Perfect the Design of the Curved Steel

6) We will Choose a Method for Bending Your Steel Based on Your Needs and the Application of the Product

7) We Bend Per Your Template and/or Drawings.

8) We have a 50,000 sq ft Shop with Ample Room to Handle Large Structural Projects and Smaller Repeat Orders.

9) We have the Right Tools with State of the Art Bending Equipment, Bend Dies, Fab Equipment and a QC Department.

10) No Need to Remove the Filling! We DO NOT fill your HSS with other Structural Members. We are able to Bend HSS Members WITHOUT adding extra Material and Weight.

11) Bend, Roll, Spiral, Fabricate, Form!!

12) Erect, Assemble & Display Award Winning Projects Featuring Curved Steel Members for the Steel Industry to See!

“It is so fun to drop in!” Sherwood Skate Park just opened and it is awesome! Filled with kids every day! Albina was thrilled to be a part of the project bending 4 lengths x 20 ft. Tube Steel 2" X 2" X .188" WALL A500 GR B to a 42 ft radius and a 46 ft radius, as well as 3 lengths x 21 ft.: 2" SCH40 A53B ERW bent to a 12 ft radius and a 5 ft radius, for the lip/rail that runs the perimeter of the park as well as for the benches kids sit and skate on.

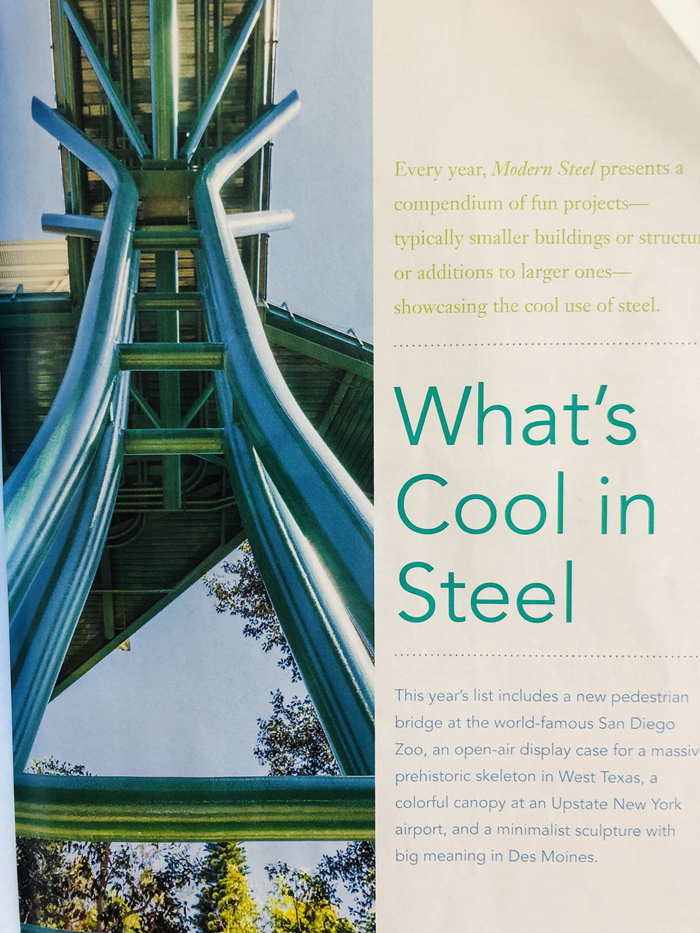

The August Issue of Modern Steel featured an article titled “What’s Cool In Steel” and one project highlighted was the Bashor Pedestrian Bridge at the San Diego Zoo (pages 23-26). Albina Co., Inc. was the bender/roller on this project. Materials rolled for this project included 24 lengths, each measuring 48 feet long, of 16” OD X .0625” wall tubing rolled to various radii including a 20 foot radius, a 50 foot radius and a 350 foot radius. Check out the pictures below and read the article for more detailed information on the fascinating curved steel bridge.

We took our daughter to tour the University of Oregon this week and we were simply in awe of the amazing facilities and buildings on campus! Our tour started on Franklin Boulevard where the University broke ground in early March on the Phil and Penny Knight Campus for Accelerating Scientific Impact. Albina Co., Inc. bent 22" OD x 1" Wall Carbon Steel Pipe to a 105 foot center-line radius for a signature sky bridge that spans Franklin Boulevard and serves as a connector between campus and other U of O research facilities. The $225 million, 160,000-square-foot first phase is slated to open in early 2020.

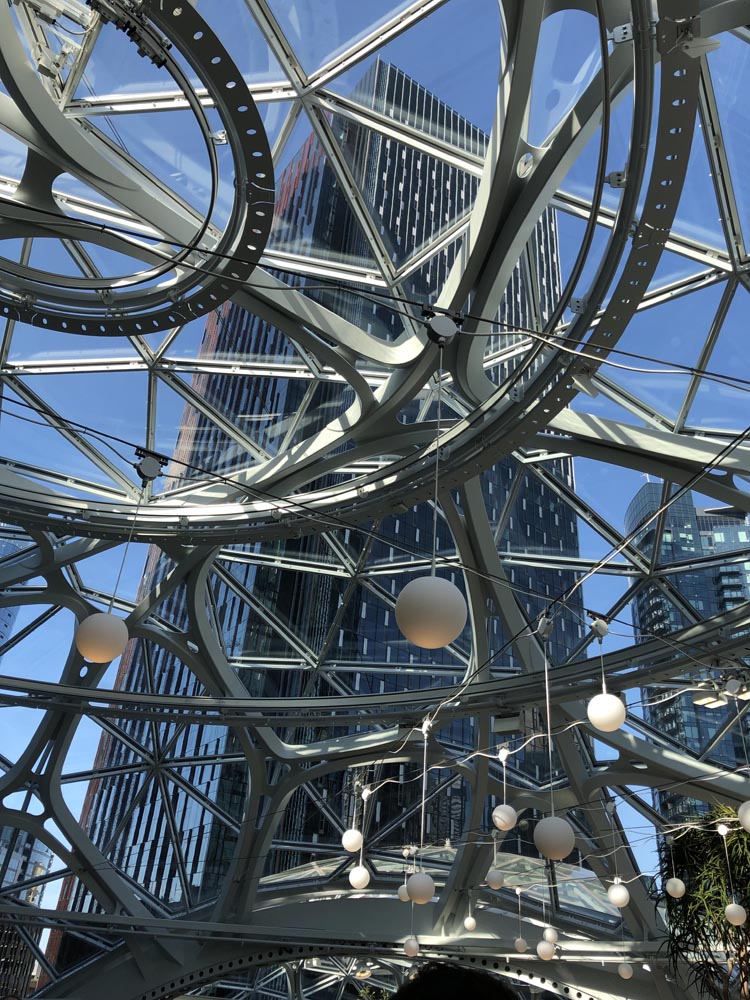

"The Spheres" in Seattle, Washington have been all the buzz lately! "The Spheres" were featured in the May 2019 Edition of Modern Steel Magazine as the buildings were awarded the AISC's IDEAS2 Presidential Award for Excellence in Fabrication! Just this last week, our VP of Sales, Brad Lund, was able to attend the award presentation ceremony at "The Spheres" in Seattle and we were awarded a plaque to display in our office. See below for some AMAZING pictures!

Albina Co., Inc. was the steel bender/roller for the Curved Steel Bio-Sphere buildings in Seattle, WA. Albina bent 750,000# and 1,050 pieces rectangular tube steel bent the easy way and a portion bent off-axis. Almost 8 miles of welding work and grinding was avoided because of Albina’s ability to bend a portion of the project. Almost NO correction was needed during fabrication or erection as the bends fit to the fixtures within 1/32nd of an inch! Albina Co., Inc. also bent the handrails and spiral staircase for the interior of the buildings.

Check out the August Issue of Modern Steel for “What’s Cool In Steel” Albina was the bender/roller on two of the featured projects including the Basher Pedestrian Bridge at the San Diego Zoo (pages 23-26) and a Des Moines sculpture titled “A Monumental Journey” by artist Kerry James Marshall (pages 30-31). We are working on securing some final install pictures of each of these projects! Stay tuned!

The last few years have been sensational for Albina Co., Inc. We have seen a great deal of change in our industry and have been fortunate to recognize growth in our capabilities, capacity and in both our shop and office team members. We are excited to introduce the newest member of our Estimating / Project Management team, Joseph (Joe) Daniels. Joe is joining Aaron Hughes, Mark King, Brad Lund, Stuart Hasman and Brian Smith in Albina's Sales department. Joe has many years of experience in the steel and fabrication industry and has worked in Albina's shop, as an Ironworker, since July 2014. Joe has developed an outstanding reputation at Albina and will be a welcomed addition to our outstanding sales and estimating team. Joe possesses a comprehensive work ethic and will service Albina's customers just as you have grown accustomed to from the other members of our team. We are confident Joe's commitment to quality and integrity will make him a valuable resource as our company and your business continue to grow. You can contact Joe or any of our other existing sales staff with your estimating and technical needs at 503-692-6010. Joe's email is jdaniels@albinaco.com. Thank you for your continued support.

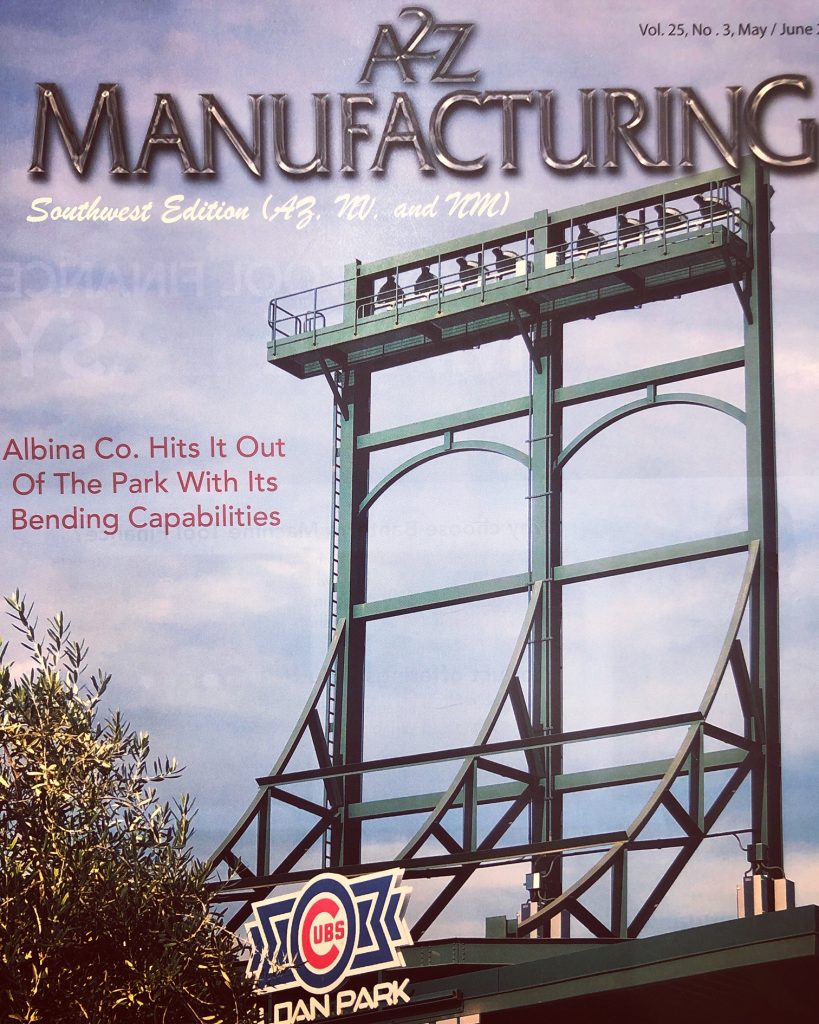

Check out the two-page feature article on Albina Co., Inc. in the May Southwest Edition of A2Z Manufacturing Magazine. We had such a great time working with Linda and Kim putting the article together.

The article highlights several projects that we have participated in specifically in the states of Arizona, Nevada and New Mexico. Our company history, philosophy and future goals are also touched on in the piece.