The American Institute of Steel Construction and the National Steel Bridge Alliance are recognizing eight bridges with 2024 Prize Bridge Awards—the structural steel industry’s highest design honor for bridges.

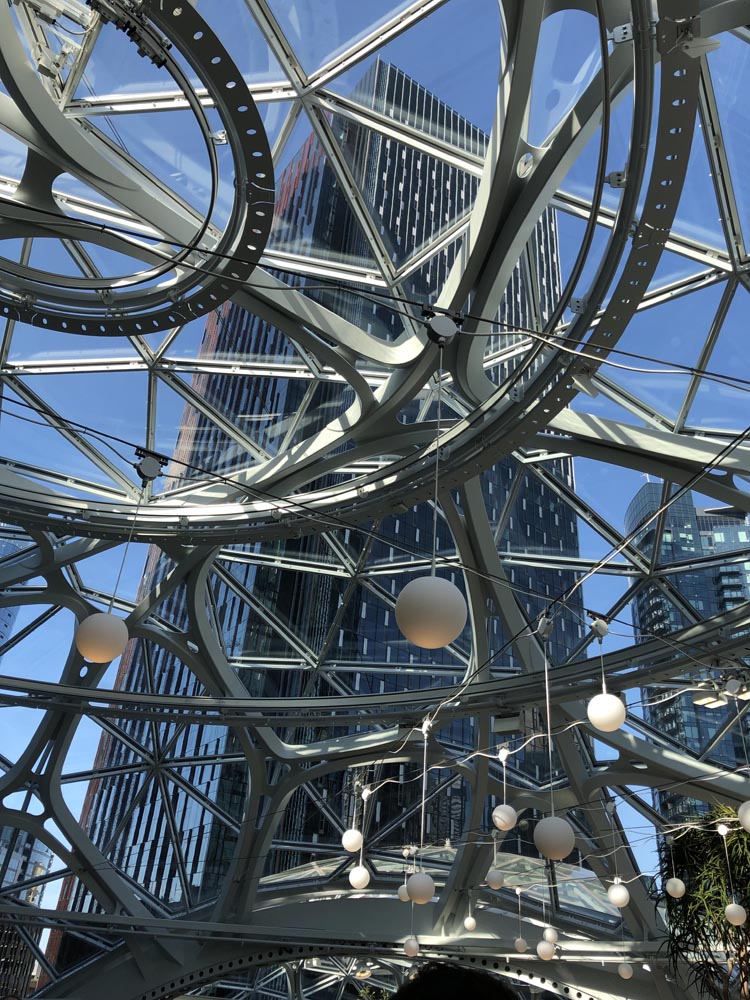

Albina bent 127,000# of tube steel for the South Bayfront Pedestrian Bridge and Horton Landing Park, Emeryville, California, a Merit Award Winner.

Albina induction bent 15 lengths of TS 16” X 16” X .625” WALL A1085 A513 to 149 ft and 289 ft radii and 9 lengths of TS 20” X 12” X .625” WALL A1085 A513 the easy way to 290 ft and 310 ft radii. Photo credit: Tom Loomis

You can see the full list of winners at aisc.org