As 2017 winds down, we would like to thank you for giving us the opportunity to serve you. We hope to have the pleasure of doing business with you for many years to come. As we reflect on the many relationships we built upon this past year, the very interesting and high-profile projects we have been a part of, as well as the challenges and obstacles we faced along the way, we are thankful that we had such a great customer base to share those experiences with. We are looking forward to a new year that will certainly bring its own set of adventures, but we are ready! WE GET IT...YOU ARE BUSY! THAT IS WHY WE VALUE YOUR TIME. It seems anymore that there isn't just a "busy time of year", every day, throughout the entire year is busy! We get that you are being pulled in many different directions with work, family, fun activities, etc. That is why we want you to know that WE VALUE YOUR TIME and boy do we have a gift for you this holiday season! The visionary concept of "videotelephony" was first popularized in the late 1870's in both the United States and Europe. The first systems were developed by AT&T Corporation, first researched in the 1950's, and failed mostly due to the poor picture quality and the lack of efficient video compression techniques. Today's video conferencing systems are no longer just for webinars. Albina has invested in a system that makes video conferencing as simple as one click in an email. Even if you do not have a camera on your end, our video call allows you to see our smiling face, while we both can talk like a telephone call. But it can go much further than that! We can share our screen with you to review drawings We can link you to our shop cameras so that you can see your job in progress We can teach you how to use the calculations application inside our website We are still learning how this can bring even more value AND respect your time. Click on this

YouTube Video to see a brief example of what we are now able to accomplish (and at the same time, receive my holiday well wishes via video!) Never tried a video call? Drop us a line and we would be happy to show you.

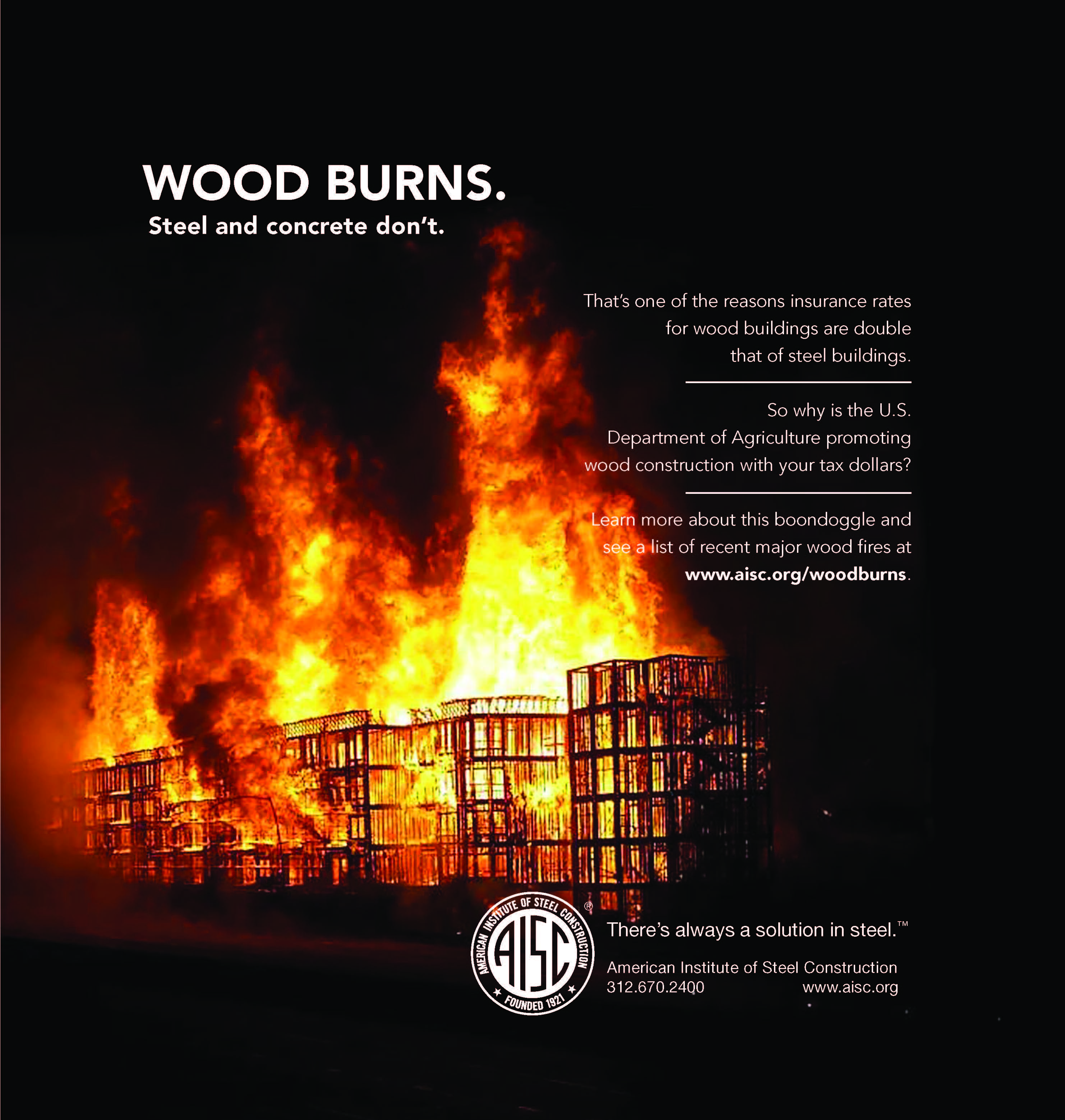

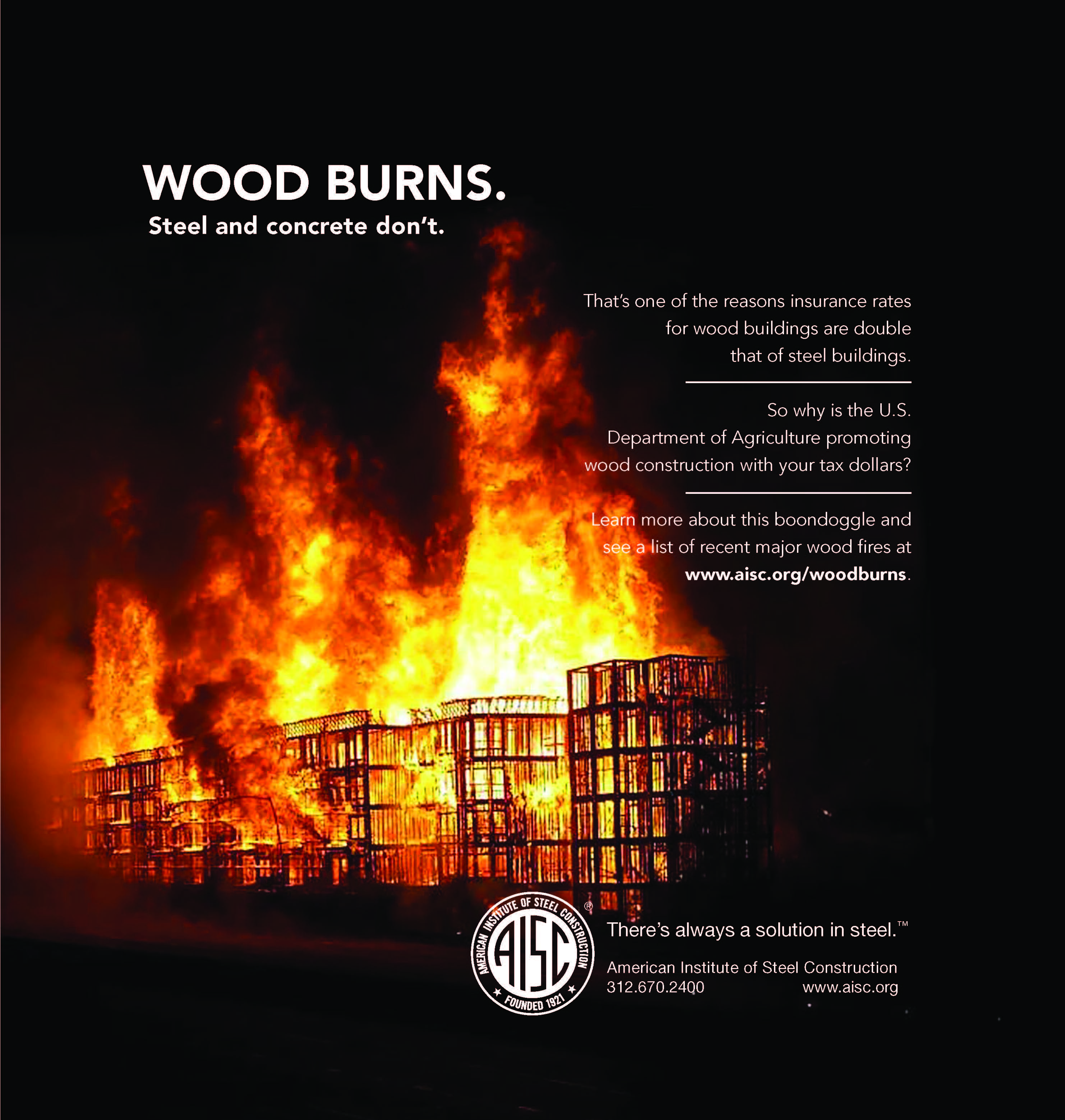

AISC Ad in USA Today's special insert titled "Construction in America"[/caption]

AISC Ad in USA Today's special insert titled "Construction in America"[/caption] AISC Ad in USA Today's special insert titled "Construction in America"[/caption]

AISC Ad in USA Today's special insert titled "Construction in America"[/caption]