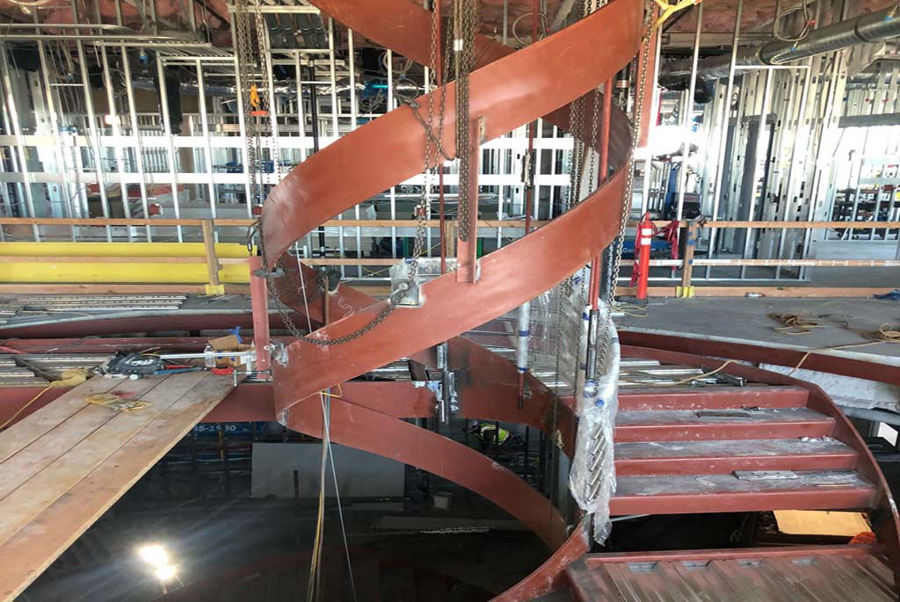

Curved steel treehouse structures provide a tranquil and relaxing break area for the employees of NVIDIA, a computer hardware manufacturer, at the corporate headquarters in Santa Clara, California. Albina Co., Inc. was the steel bender-roller on this project. We bent 55,000# of bent material including:

TS 12" X 4" X .500" WALL A500 GR B

6 pcs bent the easy way to a 28 ft radius (30 ft of bent material per pc). Material bent and trimmed by Albina.

TS 5" X 5" X .375" WALL A500 GR B

12 pcs bent to a 31 ft radius (16 ft of bent material per pc). Material bent, trimmed and drilled by Albina.

TS 8" X 2" X .250" WALL A500 GR B

89 pcs bent the hard way to an approx. 32 ft radius (approx. 18 ft of bent material per pc). Material bent, trimmed and drilled by Albina.

3" X 3" X ¼" ANGLE A36

12 pcs bent leg in to a 31 ft radius (15 ft of bent material per pc). Material bent and trimmed by Albina.

TS 3" X 3" X .250" WALL A500 GR B

4 pcs bent to a 5 ft radius (7 ft of bent material per pc). Material bent and trimmed by Albina.

TS 5" X 3" X .250" WALL A500 GR B

4 pcs bent the easy way to a 5 ft radius (7 ft of bent material per pc). Material bent and trimmed by Albina.

5" X 5" X ½" ANGLE A36

6 pcs bent leg out to a 2 ft radius (1 ft of bent material per pc). Material bent and trimmed by Albina.