Albina's number one goal is to provide customers with competitively priced

steel bending services resulting in quality products, on time. We honor our commitment to this goal by continuously fulfilling our obligations and meeting our customers needs. We have a very high regard and respect for our customers, vendors and employees and we hold many of them in very high esteem as if they were a part of our own family. We are proud of the many partnerships and relationships that we have built over the years. The reason we have such longstanding relationships in the

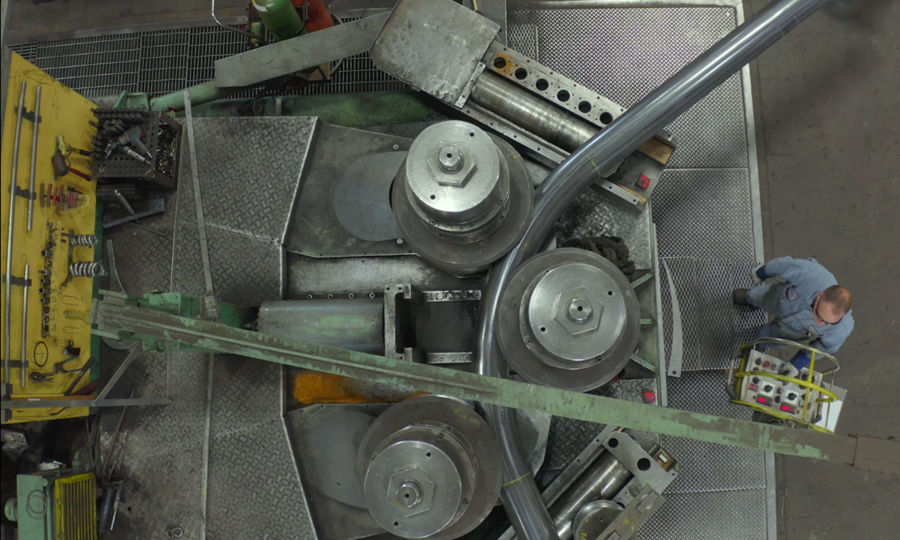

steel bending industry, is not only because we have been around for nearly 80 years, but because of the pride that we take in the quality of our work and the service that we provide on each and every job. We feel satisfied only when the commitments we have made to our partners are fulfilled. Pride is not only reflected by our team putting our hearts and souls into your end product, but can also be seen in our many efforts to improve our working environment and the community around us. a) Albina Co., Inc. donates to many local and national Charitable Organizations including CONSANO, Meals on Wheels PDX, The Hunger Drive, Assistance League of Greater Portland, Sherwood Education Foundation, Local Sports Teams, etc. b) We purchase steel from service centers in the USA. Our bent steel products are "Made In The USA" out of our facility in Oregon. c) We have taken many steps to reduce our carbon footprint by reducing our power usage. In the last 12 months we have undergone significant capital expense to "do our part" by installing a 134.4 kW solar array and we replaced every interior and exterior lighting fixture / bulb with LED replacements. d) Recent Upgrades to our phone systems and internal camera systems to increase our ability to communicate, track and share real time data seamlessly within our shop and externally with customers and vendors. e) We have made huge efforts over the last few years to bring in new equipment, service/update older equipment, and we have actually designed and built our very own, one-of-a-kind, CNC induction bending process. It is small companies like ours that will make American great again because we run an honorable business and we take pride in our work. We are all learning, that in this very difficult and scary time in our world, that it is the little things that matter and it is the intangibles that help determine who, what, when, where and why you should do business with someone. [caption id="attachment_1240" align="aligncenter" width="1000"]

Happy 4th of July! We like to spend America's Birthday with family and friends. We have spent many 4th of July weekends at the beautiful Oregon Coast, in the Central Oregon high desert, or just hanging around the neighborhood having BBQ's and enjoying the amazing Oregon summers. We wish you all a happy and safe 4th of July! [/caption]