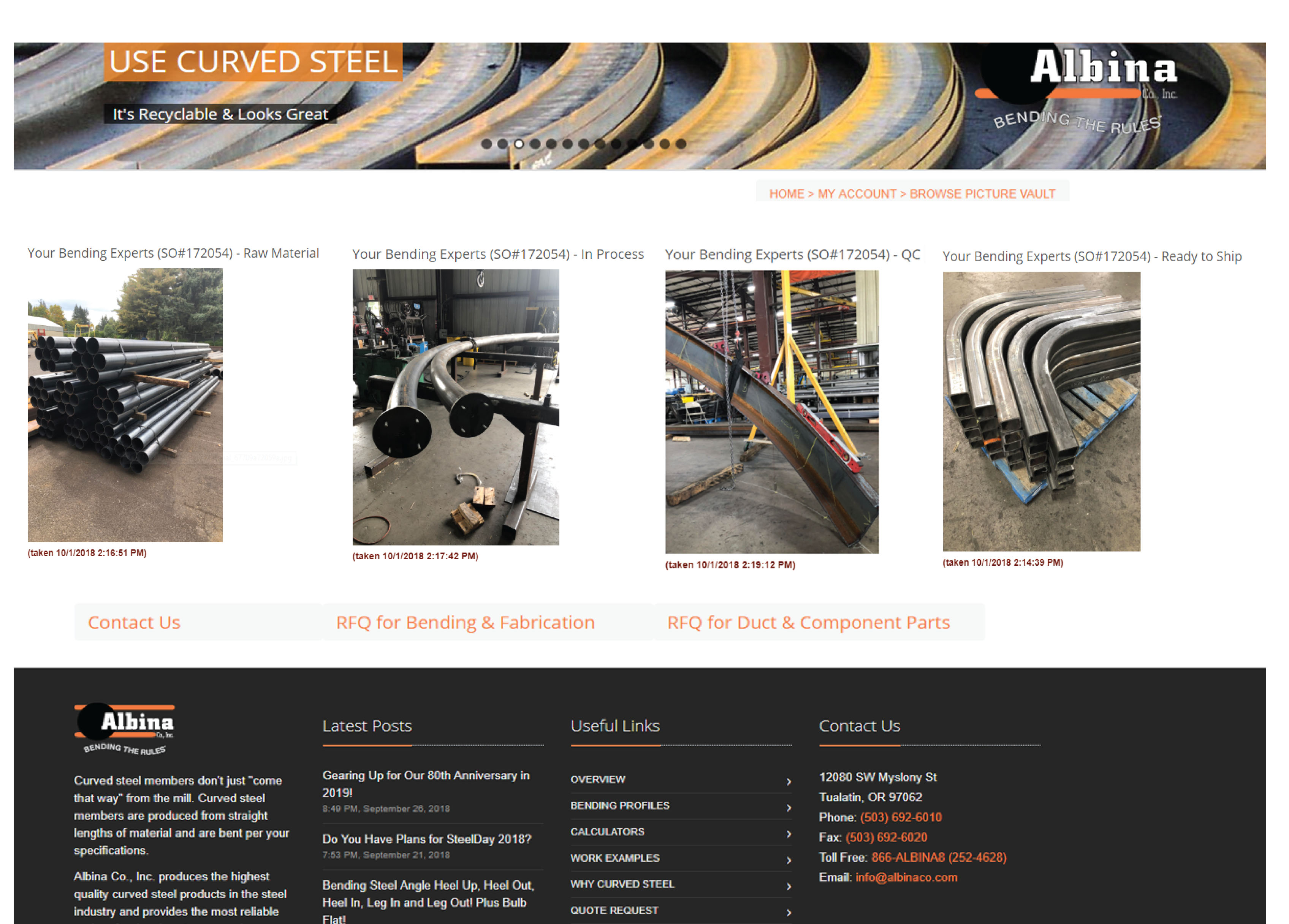

Our new "Picture Vault" has been live for almost two weeks and our customers are loving it! We have sent picture links to dozens of customers and have gotten extremely positive feedback. Customers think the vault is "cool", "informative" and "a great way to learn about the steel bending process." If you haven't heard about the vault yet, here is a recap! We recently added a new bar coding system to our shop orders which allow our operators to take pictures during various stages of a bending project. Customers can now login to a secure portion of the Albina Co., Inc. website to see their jobs in four various phases of the

steel bending process: raw material, in-process, in quality control and ready to ship.The objective is to offer yet another value-added service for our customers and to keep them well informed throughout their project. Once pictures are taken and uploaded to Albina’s internal picture vault, the project manager at the customer site will receive an email with a secure login username and password, as well as a link letting them know that they have new pictures ready to view. Pictures will be categorized based on Purchase Order Number and Project Name and will remain available for viewing indefinitely. If customers like the pictures posted in the vault, they are welcome to contact us and we will provide a JPEG image for both internal or external use. The secure site is also useful for ordering

Standard Duct & Component Parts online! So quick and easy! If you haven't ordered online yet, call us today and we will get you set-up immediately to start ordering online.

This is just the first phase of the secure site. Our plan is to provide a resource for customers to view and track other items including invoices, packing slips, order confirmations, etc.

</a

</a