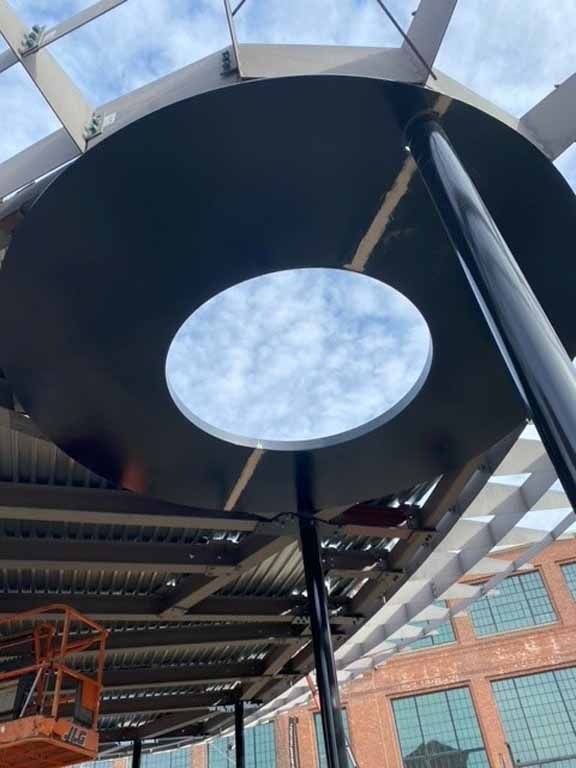

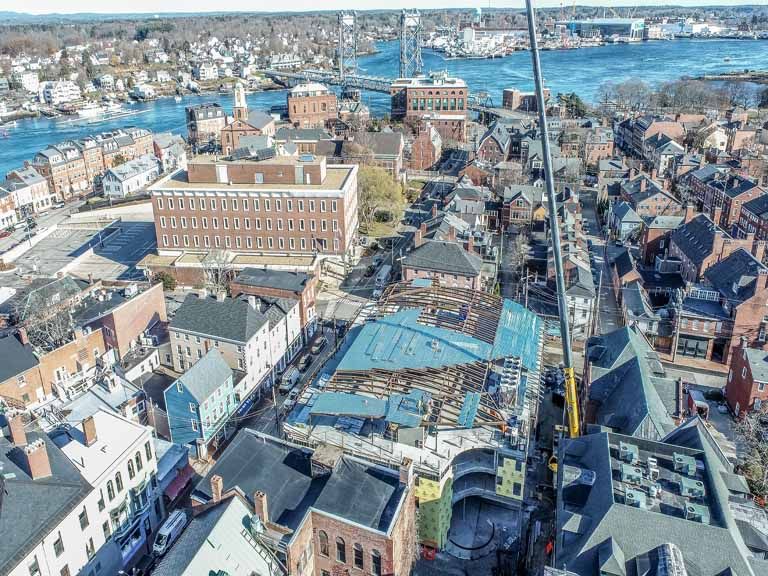

At the Chehalem Cultural Center, the Performing Arts Wing remodel is a project that beautifully marries artistry and structural innovation. This renovation highlights the use of expertly bent steel materials to achieve elegant curves and helices that contribute both to the aesthetic and functional design of the space.

Steel Components and Craftsmanship

This remodel involves the precision bending of structural steel components to exact specifications, showcasing advanced fabrication techniques:

- Tube Steel 12" X 6" X .625" WALL A500 GR C

- Detail: One length bent the easy way to a 16’-7” radius.

- Purpose: Offers smooth, sweeping lines that enhance structural integrity and visual appeal.

- Tube Steel 14" X 4" X .500" WALL A500 GR C

- Details:

- One length helically bent the easy way to a 10’-9” radius.

- Another length helically bent the easy way to a 15’-9” radius.

- Purpose: Provides complex, helical shapes to support the artistic design of the structure.

- 1¼" SCH40 A53B ERW WHEELED

- Details:

- Two lengths helically bent to a 10’-11½” radius.

- Two lengths helically bent to a 15’-5 7/8” radius.

- Purpose: Creates intricate curves for additional architectural elements, blending strength with aesthetic finesse.

- 6" X 4" X 3/8" ANGLE A36

- Detail: One length bent with the 4” leg out to a 17’-1” radius.

- Purpose: Adds angled support with a subtle radius, balancing the structural framework.

Why Steel Bending Matters

Steel bending is at the heart of modern architectural design, allowing for the creation of fluid forms that would be impossible with traditional straight-line construction. The materials used in this remodel reflect the durability and flexibility needed to bring the Performing Arts Wing’s vision to life.

The Chehalem Cultural Center's Vision

This remodel not only upgrades the Performing Arts Wing but also emphasizes the center’s commitment to innovation and excellence. By utilizing advanced steel fabrication techniques, the project ensures a lasting impact on the community and future generations of performers and audiences.

For more details on the Chehalem Cultural Center Performing Arts Wing, visit Chehalem Cultural Center.