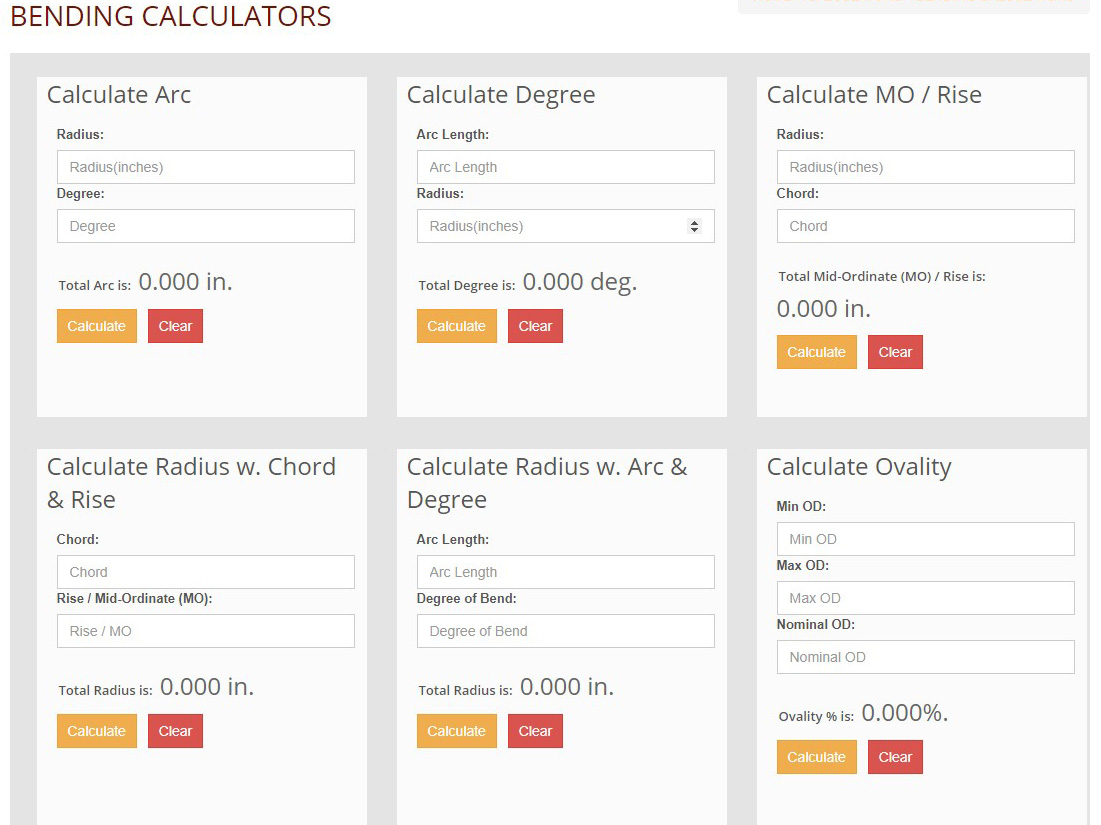

For all our customers that need assistance in calculating bending dimensions or material take-offs for bending. Look no further than Albina’s bending calculators / Curve Calculators. Albina’s bending calculators allow end users to calculate the following critical bending data:

- How to calculate the arc of a bend or curve with our Arc Calculator.

- How to calculate the degree of a bend or curve with our Degree Calculator.

- How to calculate the Mid-Ordinate (MO) / Rise of a curve or Arc with our Mid-Ordinate Calculator.

- How to calculate the radius of a curve with our Radius Calculator.

- How to calculate the ovality of a round section after bending with our Ovality Calculator.

- How to calculate the critical dimensions of a stair stringer with our Stair Stringer Calculator / Spiral Math Calculator.

- How to calculate the degree turn in plan view for a spiral staircase (spiral stringer).

- How to calculate the degree of pitch for a spiral staircase (spiral stringer).

- How to calculate the arc length for a spiral staircase (spiral stringer).

- How to quickly determine the amount of straight or tangent material needed to successfully bend a length of material or part.

Albina’s calculators can be found here: https://www.albinaco.com/calculators

Albina also specializes in plate bending, not just HSS, Pipe, Tube, and Structural Steel bending. Countless customers come to Albina for our plate rolling expertise, including bending plate into a cone configuration. Many customers require a cone calculator. There are many cone calculators available, but we typically use a calculator located here: https://i-logic.com/conecalc/. Not only will this calculator provide the end user with the critical cone dimensions, but also the cone flat pattern.