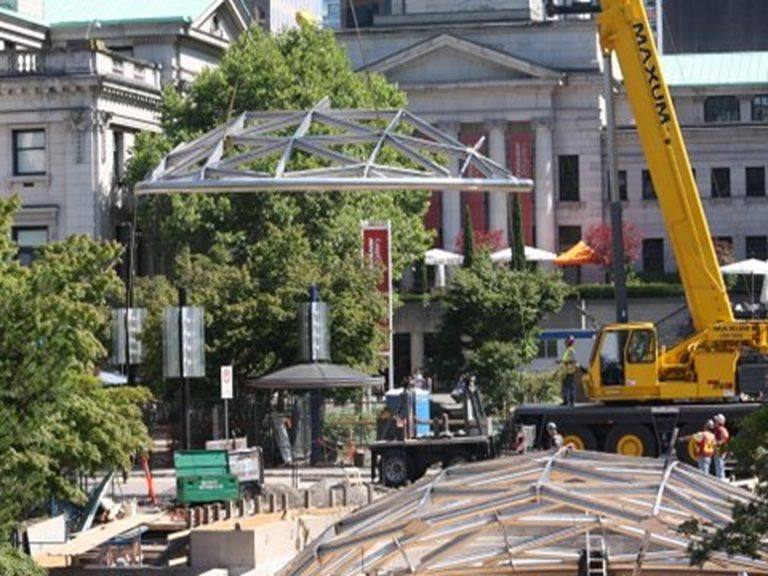

In late 2025, a striking new art installation and shade structure called Skyriver took shape in Boise, Idaho, bringing together thoughtful design, material precision, and a deep connection to place. Designed and constructed by Hua Studio, Skyriver is inspired by the “waterways that feed the Boise Valley,” translating the region’s natural systems into a sculptural form that celebrates movement, migration, and flow.

The installation’s sweeping curves and layered geometry evoke the constant motion of water as it travels across landscapes. More than a static object, Skyriver invites viewers to experience motion through form, light, and shadow. As the sun moves across the sky, the structure becomes an active participant in its environment, casting shifting patterns that echo the rhythms of the waterways that inspired it.

Constructed entirely from steel and aluminum, Skyriver is both visually light and structurally robust. Albina was proud to contribute to the fabrication of this piece, bending 16 pieces of 4-inch pipe and 16 pieces of 3.625-inch round tube to achieve the fluid, organic curves essential to the design. Precision bending was critical—each element needed to align seamlessly to maintain the sense of continuous movement while meeting the structural demands of a public installation and shade structure.

The collaboration between Hua Studio and Albina highlights the intersection of art and advanced metal fabrication, where technical expertise enables ambitious creative visions to become reality. Projects like Skyriver demonstrate how industrial processes can be leveraged to support expressive, site-specific design that enhances public space.

Photographs and videos of Skyriver were captured by Hua Studio and Wytske Van Keulen, documenting the installation from multiple perspectives and showcasing how it interacts with its surroundings throughout the day.

To learn more about Skyriver and explore additional work by the designers, be sure to visit the Hua Studio website:

https://www.huastudios.com/