This year Albina Co. played a part in 3 of DJC’s top projects of 2025! Albina did bending for components of the Legacy Silverton Emergency Department project, the Oregon State University Cordley Hall project, and the PDX Terminal Core Redevelopment Phase 1 project!

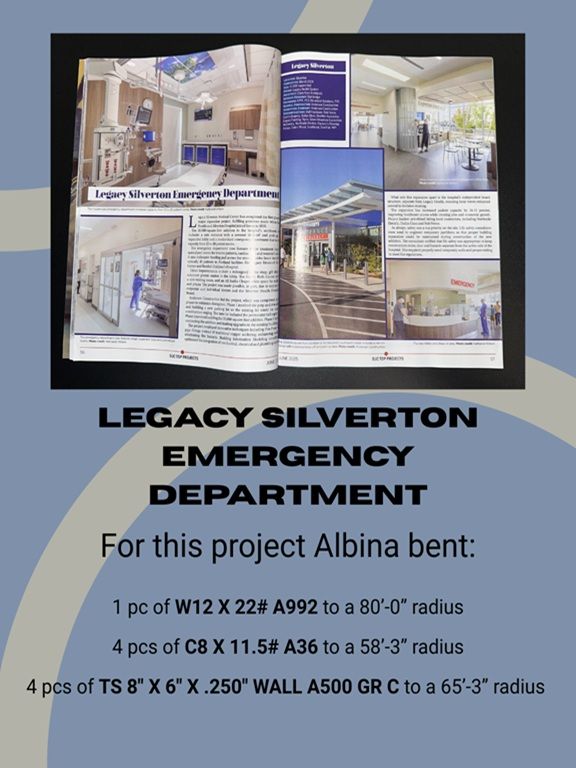

Legacy Silverton Emergency Department

Albina bent

1 pc of W12 X 22# A992 to a 80’-0” radius

4 pcs of C8 X 11.5# A36 to a 58’-3” radius

4 pcs of TS 8" X 6" X .250" WALL A500 GR C to a 65’-3” radius

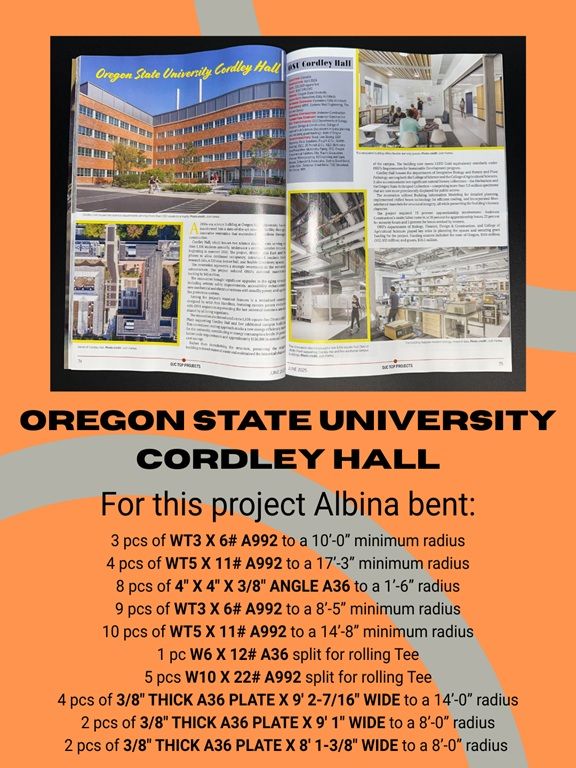

Oregon State University Cordley Hall

Albina bent

3 pcs of WT3 X 6# A992 to a 10’-0” minimum radius

4 pcs of WT5 X 11# A992 to a 17’-3” minimum radius

8 pcs of 4" X 4" X 3/8" ANGLE A36 to a 1’-6” radius

9 pcs of WT3 X 6# A992 to a 8’-5” minimum radius

10 pcs of WT5 X 11# A992 to a 14’-8” minimum radius

1 pc W6 X 12# A36 split for rolling Tee

5 pcs W10 X 22# A992 split for rolling Tee

4 pcs of 3/8" THICK A36 PLATE X 9' 2-7/16" WIDE to a 14’-0” radius

2 pcs of 3/8" THICK A36 PLATE X 9' 1" WIDE to a 8’-0” radius

2 pcs of 3/8" THICK A36 PLATE X 8' 1-3/8" WIDE to a 8’-0” radius

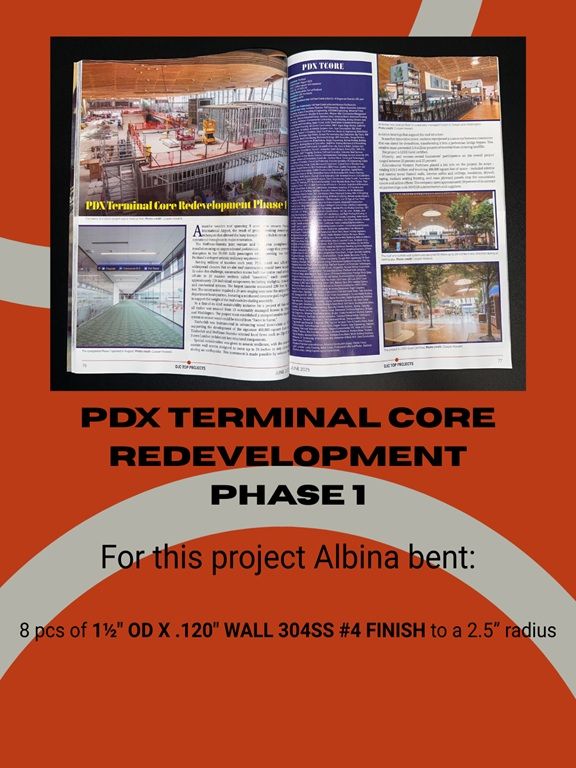

PDX Terminal Core Redevelopment Phase 1

Albina bent

8 pcs of 1½" OD X .120" WALL 304SS #4 FINISH to a 2.5” radius