Square & Rectangular Tube (HSS)

Albina has the ability to bend both square and rectangular tubing. For rectangular tubing we can bend both the easy way (against the weak axis) and the hard way (against the strong axis). We can even provide Multi-Plane bending where we are bending both the easy way AND the hard way.

Albina is a unique shop in that we can bend very small square materials such as TS ½” x ½” x .049” wall all of the way up to very large materials such as TS 20” x 12” x .625” wall, which happens to be the largest size that mills produce. Albina actually has a larger capacity they TS 20” x 12” x .625” wall, which means we can bend materials larger than what the mills produce!

Square and rectangular tubing is also known as HSS (hollow structural steel).

We can bend all types of pipe and tubing including aluminum, stainless and carbon steel. We even bend specialty materials such as copper, zirconium and titanium.

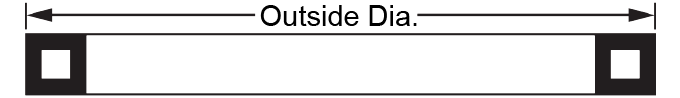

Square and rectangular tubing is always called out the same way. The first two numbers designate the size of the material (in inches). The last number (typically represented as a decimal) defines the thickness of the tubing. An example callout for standard rectangular tubing would be TS 8” x 6” x .375”. This tubing measures 8” long x 6” wide and has a wall thickness of 3/8”. You know this is rectangular tubing because the sides are not equal.

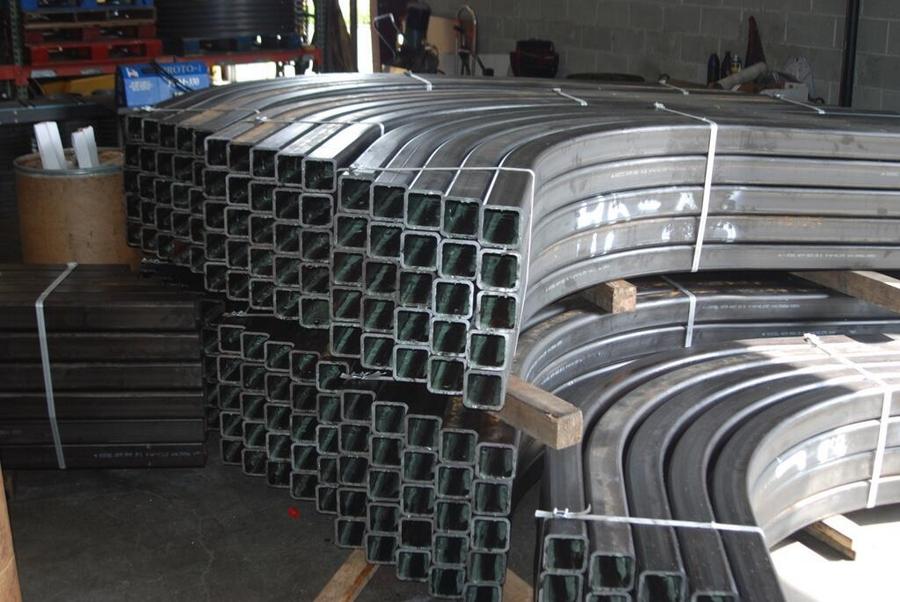

Square and rectangular tubing can be bent with every bending process we have available in our shop. Processes include draw bending, roll bending, increment hot bending, increment cold bending, induction bending and can even be bent in our plate roll.

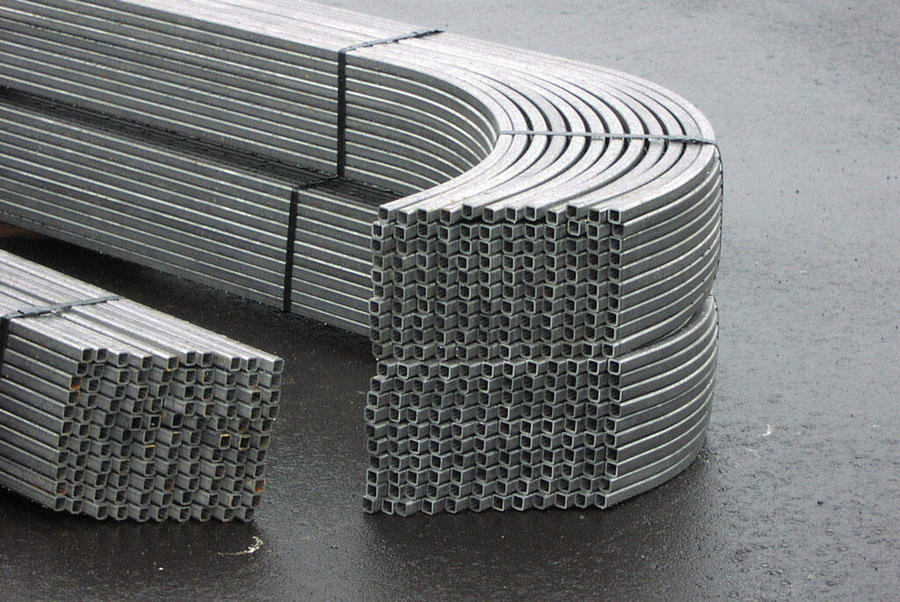

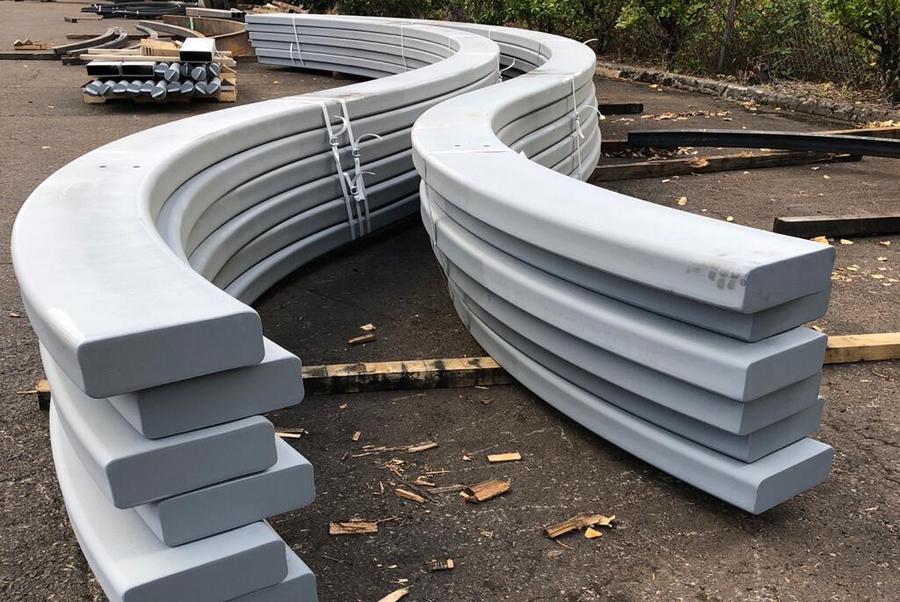

We are unique in how we bend square and rectangular (HSS) for a number of reasons. When we roll bend HSS we typically fill the material with mandrels, where we turn the hollow material into a solid. This helps minimize distortion without increasing the thickness of the material. Also during roll bending we use custom made radius corner tooling to match the radius corner of different thicknesses of HSS material. This match between tooling and material result in much higher quality bends. When we bend stringers for spiral staircases we do not fill the HSS material with permanent structural members to control distortion. Instead, we have developed methods to hot bend or induction bend HSS materials to a spiral configuration without filling the hollow part of the material. This unique process allows our customers to take HSS stringers for their staircases without added weight or inconveniences of filler materials.

Carbon square and rectangular materials (mill produced) are classified as ASTM A500 resulting in a yield point (psi) of 39,000 minimum for Grade A and 46,000 minimum for Grade B.

We bend all stock lengths as well as non-stock lengths. Stock lengths come as short as 20 feet and then come in various options up to 60 feet long.

Square and Rectangular materials can be used in virtually any application. Structural (roof trusses), ornamental (staircases), recreational (bike racks), manufacturing (various widgets) and artistic. Virtually, anything that needs to bend, can be, and is designed out of square and rectangular materials (HSS materials).

SHOW ME MORE WORK EXAMPLES!

ARCHITECTURAL INSTALLS, SPIRAL STAIRCASES & OEM PARTS

Capacities Chart

| Section | 3D Image | 2D Image | Photo | Capacities |

|---|

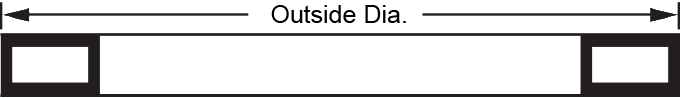

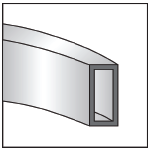

| Rectangular Tube the Hard Way |  |

|

|

20" x 12" x .625" (Maximum mill produced size-bending capacity is greater) |

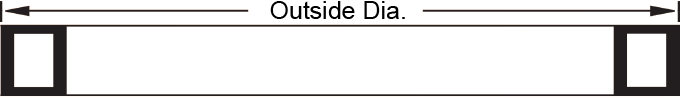

| Rectangular Tube the Easy Way |  |

|

|

20" x 12" x .625" (Maximum mill produced size-bending capacity is greater) |

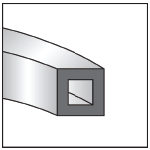

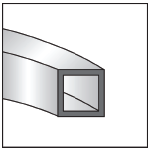

| Square Tube |  |

|

|

16" x 16" x .625" (Maximum mill produced size-bending capacity is greater) |

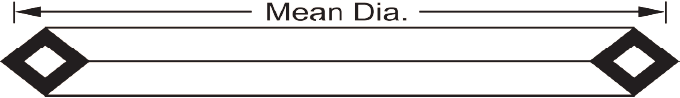

| Square Tube Diagonally |  |

|

|

16" x 16" x .625" (Maximum mill produced size-bending capacity is greater) |