Pipe & Tube

Albina was founded as a pipe bending company; in fact our original name was "Albina Pipe Bending" before changing to Albina Co. Albina has been bending pipe cold and hot since 1939. One of our first bending machines to roll pipe was made from the transmission of a Ford Model-T. We have the ability to process materials that are as small as 3/16” OD through 28” OD. This range of capabilities allows Albina to produce virtually anything that needs to bend.

Pipe and tubing is also known as HSS (hollow structural steel), just like square and rectangular tubing, since it is hollow.

We can bend all types of pipe and tubing including aluminum, stainless and carbon steel. We even bend specialty materials such as copper, zirconium and titanium.

Pipe and tubing are specified in different ways. Pipe is NOT called out by the OD size of the material and is not called out with an easily identifiable thickness. For example 2” Sch40 pipe measures 2 3/8” OD x .154” wall. The 2” is identifying the theoretic ID measurement of standard pipe. The Sch40 detail identifies the material thickness and weight per ft. Sch40 is the most common call out for pipe, it is also called "standard" wall for many different pipe sizes. Other more common schedules are Sch10, Sch40, Sch80 and Sch160. Each schedule has a different thickness and weight per foot associated with it. Furthermore, each pipe size is different. For example 2” Sch40 is not the same thickness and weight per foot as 4” Sch40. The schedules are specific to the pipe size. The best advice is to get a pipe chart where everything is clearly defined or refer to our Conversion Charts, Weights and Dimensions section. For tubing the specifics are much clearer. The OD dimension is defined and the thickness is defined in the material callout. For example 2” OD x .065” wall truly measures 2” OD with a 1/16” wall thickness.

Like square and rectangular tubing, round tubing and pipe can be bent with virtually every bending process we have available in our shop. Processes include draw bending, roll bending, increment hot bending, increment cold bending and induction bending. The only exception is the plate roll.

We can bend all types of pipe and tubing including aluminum, stainless and carbon steel. We even bend specialty materials such as (zirconium and titanium). Carbon pipe (mill produced) is classified as ASTM A53 (most commonly) resulting in a yield point (psi) of 30,000 minimum for grade A and 35,000 for grade B. Carbon tubing (mill produced) are most commonly classified as ASTM A500B resulting in a yield point (psi) of 46,000 minimum for Grade B.

We bend all stock lengths as well as non-stock lengths. For pipe stock lengths come as short as 21 feet and 40 feet long. For tubing the minimum length is typically 20 feet and the longest is typically 40 feet.

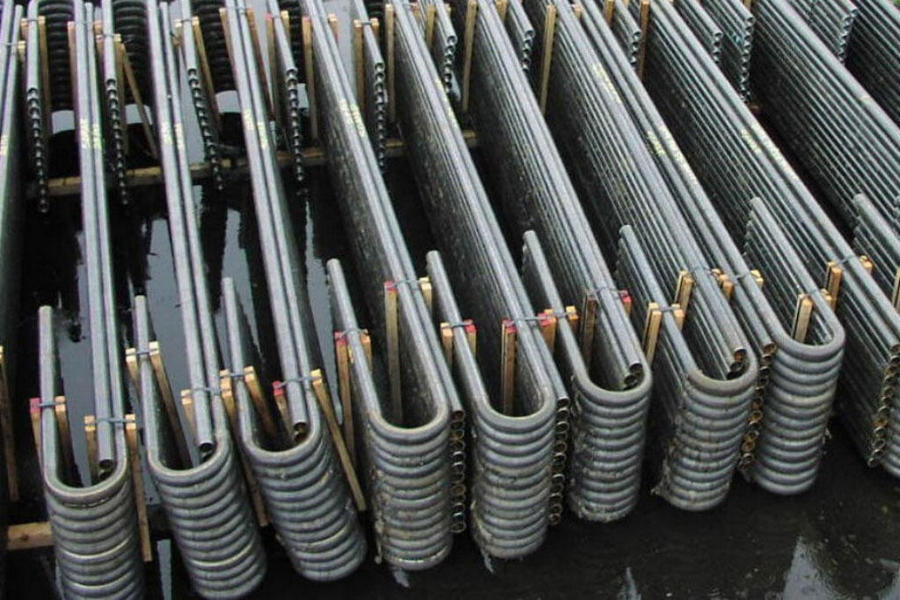

Tubing and pipe can be used in virtually any application but are most commonly used as railings, recreational products (play grounds, bike racks, goal posts), industrial products (boiler tubes, heat exchangers, piping systems) and curved members of canopies and awnings.

SHOW ME MORE WORK EXAMPLES!

ARCHITECTURAL INSTALLS, SPIRAL STAIRCASES & OEM PARTS

Capacities Chart

| Section | 3D Image | 2D Image | Photo | Capacities |

|---|

| Round Tube & Pipe |  |  |  | Roll/Cold Bending: 3⁄16" OD through 28" OD Induction/Hot Bending: 6" OD through 20" OD Rotary Draw/Mandrel Bending: ½" OD through 6" pipe (Sch80) |